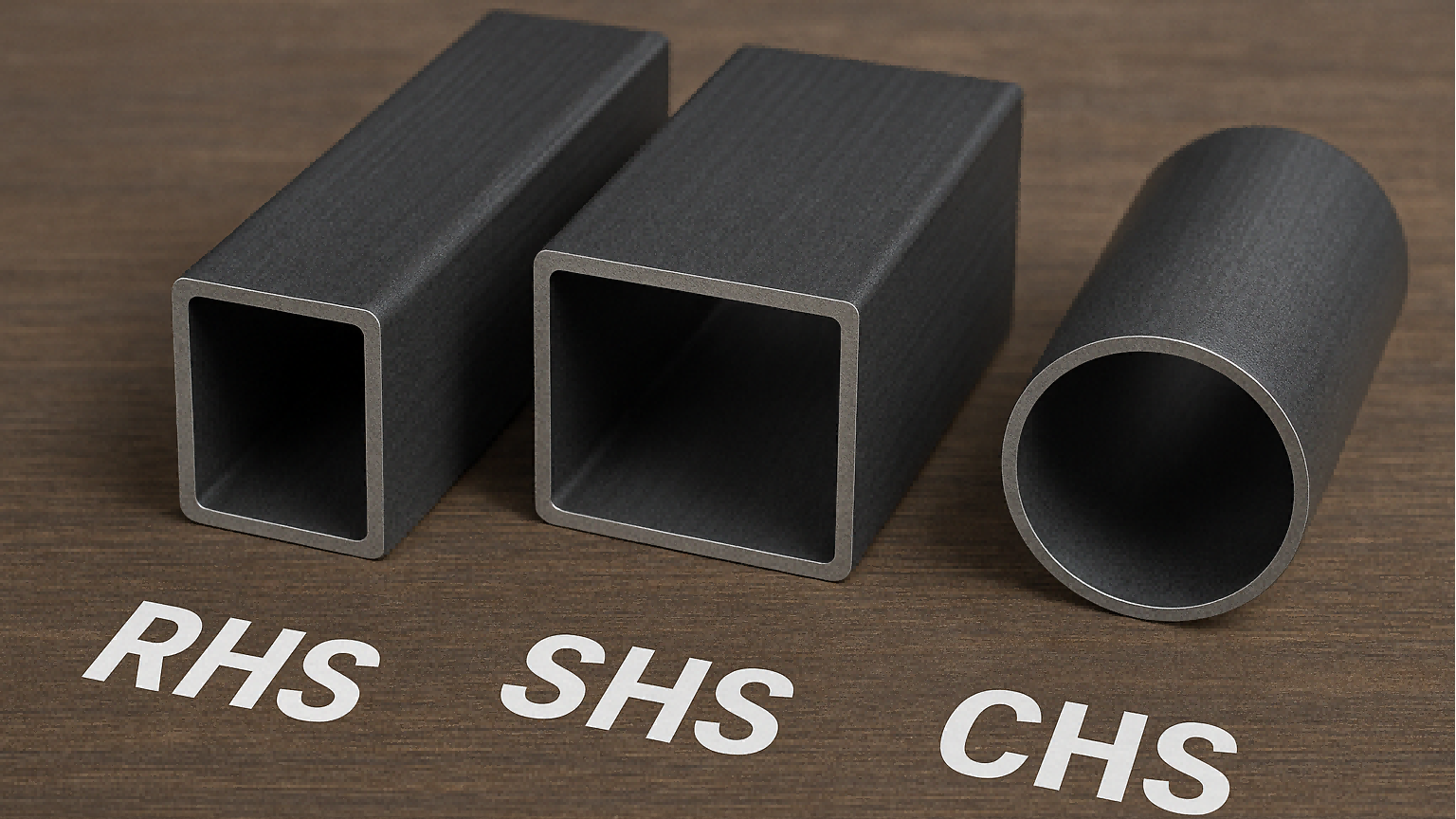

Steel hollow sections are widely used in modern construction, engineering, and manufacturing due to their structural efficiency and versatile geometry. Among them, RHS (Rectangular Hollow Section), SHS (Square Hollow Section), and CHS (Circular Hollow Section) are the most common forms. In this article, we will explore the definitions, properties, applications, and advantages of these steel profiles.

What is a Hollow Section(by WIKIPEDIA)?

Hollow sections are tubular steel products with a hollow cross-section. Depending on their geometry, they are categorised as:

These hollow sections are typically made of structural carbon steel and are available in hot-finished or cold-formed variants. They offer excellent load-bearing capacity, torsional rigidity, and surface area optimisation for welding and connections.

Types of Hollow Section Steel

1. RHS Steel – Rectangular Hollow Section

RHS steel tubes feature a rectangular cross-section and are ideal for structural applications requiring high bending strength and directional load-bearing. The flat surfaces of the RHS allow easy welding and bolting.

-

Common applications: Beams, columns, frames, bracing

-

Surface finish: Black, pre-galvanised, hot-dip galvanised

-

Standards: ASTM A500, EN 10210, JIS G3466

2. SHS Steel – Square Hollow Section

SHS steel pipes are symmetrical in both directions, offering balanced strength and aesthetic appeal. They are commonly used in architectural elements and modular steel construction.

-

Common applications: Railings, gates, steel structures, scaffolding

-

Surface finish: Galvanised, painted, oiled

-

Advantages: Torsional rigidity, compact design

3. CHS Steel – Circular Hollow Section

CHS pipes have a circular profile that provides uniform load distribution and resistance to wind and torsion. They are often used in applications where aesthetics and smooth appearance are important.

-

Common applications: Architectural columns, towers, fencing posts

-

Key features: Efficient under compression and bending

-

Coatings available: Zinc-coated, epoxy-painted

Comparison Chart of RHS vs SHS vs CHS

| Feature | RHS Steel | SHS Steel | CHS Steel |

|---|---|---|---|

| Shape | Rectangular | Square | Circular |

| Strength Direction | One-way | Balanced | Uniform |

| Welding Surface | Wide & flat | Flat | Curved |

| Aesthetic Appearance | Industrial | Clean/Modern | Smooth/Architectural |

| Typical Use | Frames, Beams | Railing, Scaffolds | Columns, Masts |

Steel Hollow Section Sizes & Thickness

Steel hollow sections come in a variety of dimensions and wall thicknesses to suit different structural needs.

| Type | Common Sizes (mm) | Thickness (mm) | Length (m) | Material |

|---|---|---|---|---|

| RHS | 40×20 to 700×300 | 0.5 – 29.75 | 6 / 12 or cut-to-length |

Q235B(ASTM A36、S235JR、SS400、St37-2) Q355B(ASTM A572 Gr.50、S355JR、SM490B、St52-3) |

| SHS | 20×20 to 500×500 | 0.5 – 29.75 | 6 / 12 or cut-to-length |

Q235B(ASTM A36、S235JR、SS400、St37-2) Q355B(ASTM A572 Gr.50、S355JR、SM490B、St52-3) |

| CHS | 1/2″ – 26″ ( DN15 – DN650) | Sch10/ 40/ 120/ 160 | 6 / 12 or cut-to-length |

Q235B(ASTM A36、S235JR、SS400、St37-2) Q355B(ASTM A572 Gr.50、S355JR、SM490B、St52-3) |

Applications of Hollow Section Steel

RHS, SHS, and CHS steel are suitable for a wide range of structural and industrial uses:

-

Construction Industry: Buildings, bridges, purlins, trusses

-

Infrastructure Projects: Highway barriers, pedestrian walkways

-

Mechanical Use: Equipment frames, conveyors

-

Architecture: Facades, handrails, signage

-

Furniture & Decorative: Steel tables, shelving frames

RHS, SHS, CHS: How to Choose?

| Application Type | Recommended Section |

|---|---|

| Load-bearing frames | RHS steel |

| General structures & frames | SHS steel |

| Aesthetic columns & towers | CHS steel |

| Welding-required designs | RHS or SHS |

| High torsion resistance | CHS steel |

When deciding among RHS, SHS, or CHS, consider:

-

Load direction

-

Joint type (welded/bolted)

-

Aesthetic requirements

-

Corrosion environment

Surface Finishes & Coatings

Steel hollow sections are available in various surface treatments:

-

Hot-dip galvanized – corrosion-resistant for outdoor use

-

Pre-galvanized – economical zinc coating

-

Black steel (uncoated) – for indoor or structural use

-

Painted or powder-coated – for aesthetic or specific environments

Buy RHS, SHS, and CHS Steel from HHY Steel Group

HHY Steel Group offers a complete range of RHS steel tubes, SHS steel pipes, and CHS hollow sections in various sizes, thicknesses, and finishes. As a professional steel structure and pipe manufacturer, we provide:

-

ODM & OEM services

-

Advanced processing: cutting, drilling, welding

-

Galvanizing and surface treatment

-

International certifications (EN, ASTM, JIS)

-

Fast global delivery

📧 Contact us at: info@hhysteelstructure.com

🌐 Website: www.hhysteelstructure.com