Red iron buildings have become the go-to choice for durable, long-lasting steel structures across various industries—from agriculture and warehouses to commercial buildings and custom barndominiums. Known for their signature red-oxide coated steel I-beams, these structures combine strength, affordability, and ease of construction. In this article, we’ll explore what red iron buildings are, their benefits, construction details, and how they compare to other building types.

What Are Red Iron Buildings?

Red iron buildings are steel structures that use I-beams coated in red oxide primer. This coating helps prevent corrosion during storage and construction. The I-beam design (shaped like a capital “I”) allows for exceptional load-bearing capacity while minimizing steel usage, making them efficient and cost-effective.

These buildings are often used in industrial applications but are also growing in popularity for residential and agricultural uses. They are commonly available in sizes such as 40×60, 60×40, 30×70, and 80×120 to suit different needs.

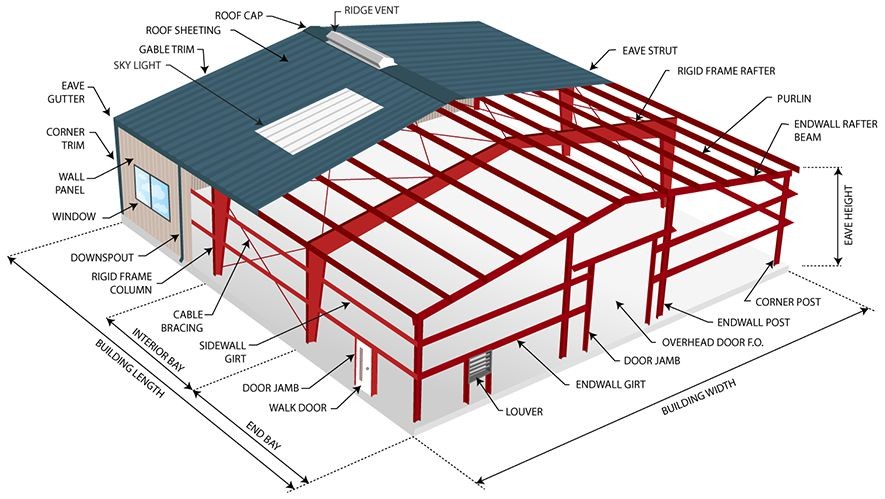

METAL BUILDING FRAMING DETAILS

PRIMARY FRAMING

Solid Red Iron I-Beam Framing:

Each I-beam in red iron buildings is manufactured with a continuous weld bead using submerged arc welding technology operated by automated machines. This method enhances consistency and structural integrity across the entire steel frame system.

End Wall Framing and Structural Columns for Red Iron Metal Buildings:

Depending on your red iron building construction requirements, end wall columns and frames are fabricated from cold-formed, rolled, or assembled “I” sections to deliver optimal load-bearing support.

SECONDARY FRAMING

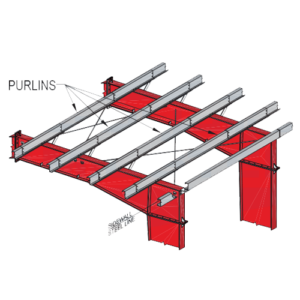

Purlins

To meet structural needs, purlins are available in 8”, 10”, or 12” sizes. In General Steel buildings, they are optionally mounted on the rafters with overlaps ranging from 12” to 16”. This overlap enhances the overall structural stability while also offering a cost-effective framing solution.

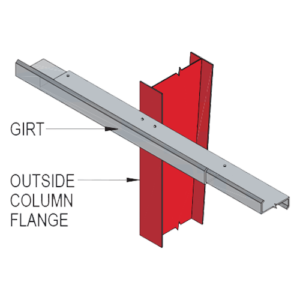

Girts

Made from cold-formed Z-sections, girts come in 8”, 10”, or 12” depths to meet different design loads. These components conform to ASTM-A570 standards, providing yield strengths between 50,000 and 55,000 psi. For enhanced structural performance, jack materials are used in specific areas.

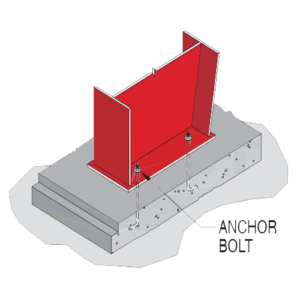

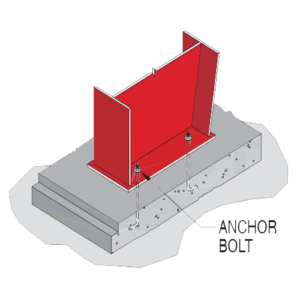

Base Angle

This is a continuous steel angle provided to fasten the wall sheeting to the foundation. It is secured to the concrete slab using ramset anchors or equivalent fasteners, typically handled by the site contractor. This connection is crucial for the overall stability of General Steel building systems.

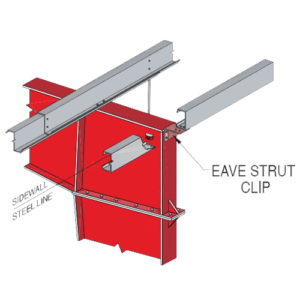

Eave Strut

Positioned along the top edge of the walls at roof level, the eave strut is a cold-rolled C-shaped member that reinforces the building perimeter. In General Steel buildings, it helps create a sealed transition at the eave line, contributing to the structure’s weather resistance.

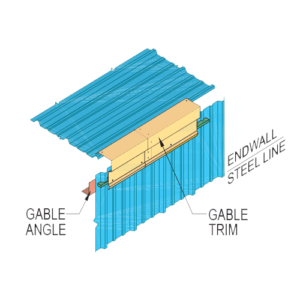

Sheeting Angle

This continuous angle is installed along the rake edges of the building, allowing for smooth and secure attachment of roof and wall panels. It simplifies sheeting installation and helps maintain the integrity of the cladding system in General Steel structures.

3. FASTENERS & BRACING

Bolts and Fasteners

General Steel structural bolts meet requirements of ASTM standards: A325 for primary frame connections, A307 for secondary framing.

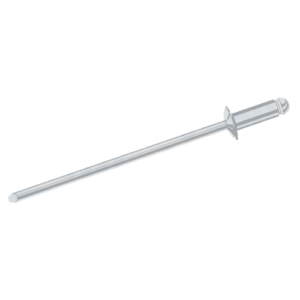

Self Drilling and Self Tapping Fasteners

Are pre-assembled with neoprene washers and metal caps to help ensure weather tightness of your steel building. This feature is one of many that separates metal buildings from traditional construction, as steel buildings are designed not to leak when present potential water damage.

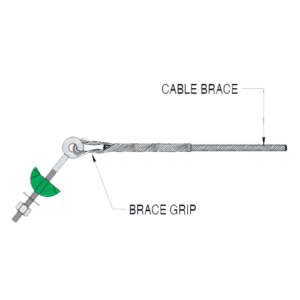

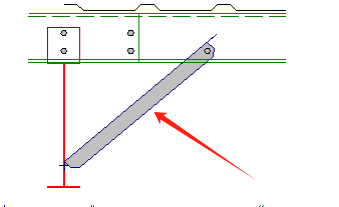

Bracing

For General Steel buildings either diagonal rod or cable bracing may be supplied for roof and walls to remove longitudinal load from the structure as needed.

Angle Flange Bracing

Is provided for the connection of the rigid frame to the purlins and girts. This ensures that allowable compression levels are adequate for any combination of loadings.

4. SHEETING AND RIDGE CAP

All Coil Steel

All Coil Steel with Galvalume coating standard (1.25oz – hot dipped) on each side helps prevent deterioration of the steel sheeting.

Deeper High Rib

Deeper High Rib with more frequent corrugations, provides extra strength for the steel building system.

Ridge Cap Panel

Includes the slope and profile of General Steel buildings to ensure that all sheeting components line up for proper alignment. Also, no overlap is required and the system is engineered to prohibit pinholing into the building through the roof.

Purlin Bearing Rib

The purlin bearing rib provides a better weather tight seal between the roof sheets on your steel building.

5. SEALANTS, TRIM, FLASHING

Sealants

For roof sidelaps, endlaps and flashing gables is provided to help prevent weather tightness. Nominal 3/8” x 1/8” grey tape sealant ensures reliable sealant for ease of installation.

Trimming and Flashing

Trimming at rake (gable) corners and eaves is provided for all General Steel buildings with standard trim material for a finished look. This is also a deterrent to moisture, insects, and dirt getting into the building.

Conclusion

Red iron buildings offer unmatched durability, strength, and adaptability. Their I-beam structure ensures robust framing, while customizable kits simplify the building process for both professionals and experienced DIYers. Whether you’re planning a warehouse, workshop, or barndominium, red iron steel buildings are a smart investment for the long haul.

Interested in a quote or kit? Reach out to our red iron building experts for pricing and customization options.

HHY Steel Structure – Building Strength for Generations.

📩 Get a Quote: info@hhysteelstructure.com

🌐 Visit Us: www.hhysteelstructure.com

HHY Steel Structure — Global Expertise. Factory Direct. Built to Last.