Introduction

When it comes to structural steel beams, terms like I-beam, wide flange beam (WF beam), W-beam, and even brown beam often appear interchangeably. However, each of these components has distinctive properties, strengths, and applications. Choosing between an I-beam vs wide flange beam can directly influence the stability, cost, and efficiency of your project.

This article will explore the differences between these beam types, their structural features, and where they are most commonly used.

I-Beam: Features and Applications

Distinctive Shape and Design

An I-beam steel is characterized by a narrow flange connected by a vertical web, forming the shape of the capital “I.” The web and flange of an I beam allow it to carry loads efficiently with a strong strength-to-weight ratio.

Load Distribution

The relatively thinner flanges concentrate material where it best resists bending and shear, making structural steel I beams highly effective for straightforward load conditions.

Versatility in Structures

From i beam trusses to supporting floor loads, I-beams are versatile components that adapt to different frameworks. They integrate smoothly with steel beam components like joists and girders.

Common Applications

-

Commercial buildings and warehouses

-

Mezzanine expansions

-

Truss systems and roof structures

-

Light industrial frameworks

Wide Flange (WF) Beam: Features and Applications

Wide Flange Design

Unlike traditional I-beams, wide flange steel beams (also called W-shaped steel or W beams) have broader flanges and a deeper profile. This design provides higher load-bearing capacity and better resistance to bending.

Superior Depth and Strength

The wide flange beam vs i beam debate often centers on depth. A WF beam’s larger structural depth enables it to span longer distances while handling heavier loads, making it more suitable for demanding industrial projects.

Load-Bearing Flexibility

WF beams excel in applications with variable loads. Their robustness makes them ideal for structures exposed to dynamic forces such as wind, seismic activity, and heavy machinery vibrations.

Common Applications

-

Bridges and large-span frameworks

-

Stadiums and arenas

-

Aircraft hangars

-

Petrochemical facilities

-

Heavy manufacturing plants

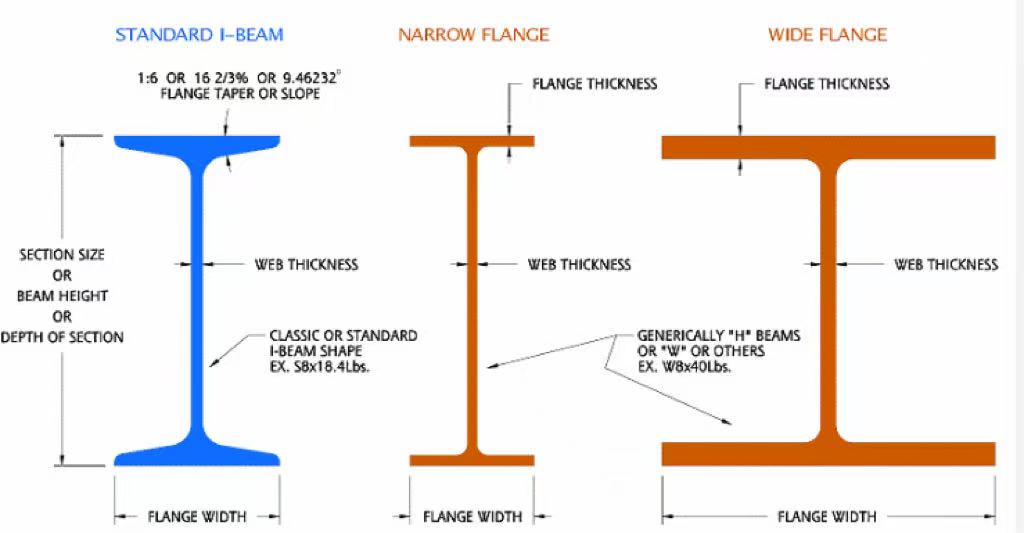

I-Beam vs W Beam vs S Beam

While I-beams focus on efficiency and adaptability, W beams (wide flange beams) provide superior load support. S beams (standard beams) fall somewhere in between, with tapered flanges that differ from the straight flanges of W beams.

Knowing the difference between i beam vs s beam, i beam vs w beam, and wide flange i beams helps engineers select the right component for performance and cost optimization.

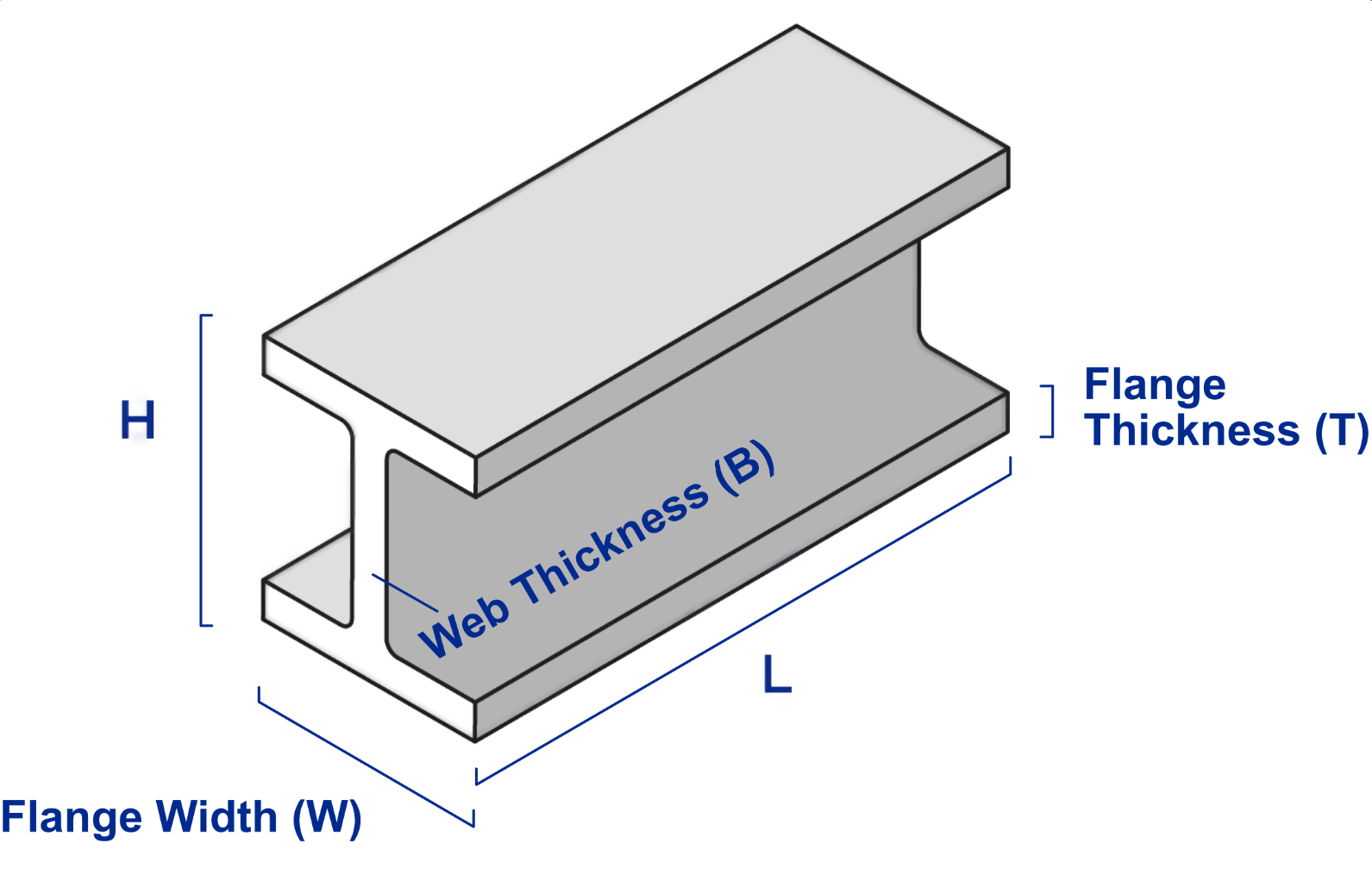

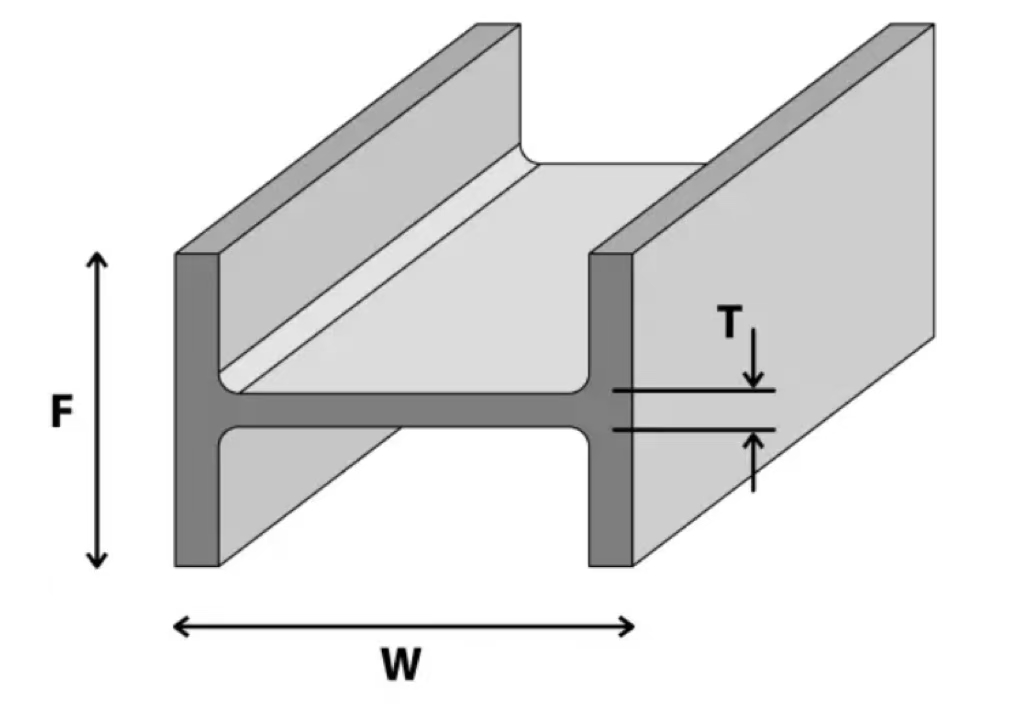

Key Structural Elements: Web and Flange

Every beam is defined by its web (vertical element) and flange (horizontal elements). The thickness, depth, and width of these parts determine how a beam reacts under stress. For example, a web flange i beam performs differently from a wf beam with wider horizontal plates.

Why Choose HHY Steel Structure?

At HHY Steel Structure, we provide a complete range of load beams and structural steel I beams tailored to international standards. Our services include:

-

Precision fabrication of I-beams, W beams, and WF beams

-

Surface treatments such as galvanizing, blasting, and painting

-

Custom cutting, welding, and cambering

-

Reliable logistics for on-time project delivery

Whether you need I-beam structures for commercial spaces or wide flange beams for heavy industrial facilities, HHY offers the expertise and manufacturing capacity to meet your requirements.

Conclusion

The choice between I-beam vs wide flange beam depends on project size, load requirements, and structural design. I-beams remain efficient for standard frameworks, while WF beams dominate in large-scale, high-load applications.