With the development of the construction industry, steel structures have evolved to suit various applications. A common challenge for beginners is choosing between H-shaped and box-shaped columns. To decide correctly, one must understand their structural advantages and match them with project needs. It’s not about which is more common, but which is more suitable for specific loads, functions, and site conditions.

First, we need to understand what these products are and how they are defined.

H-shaped steel column:

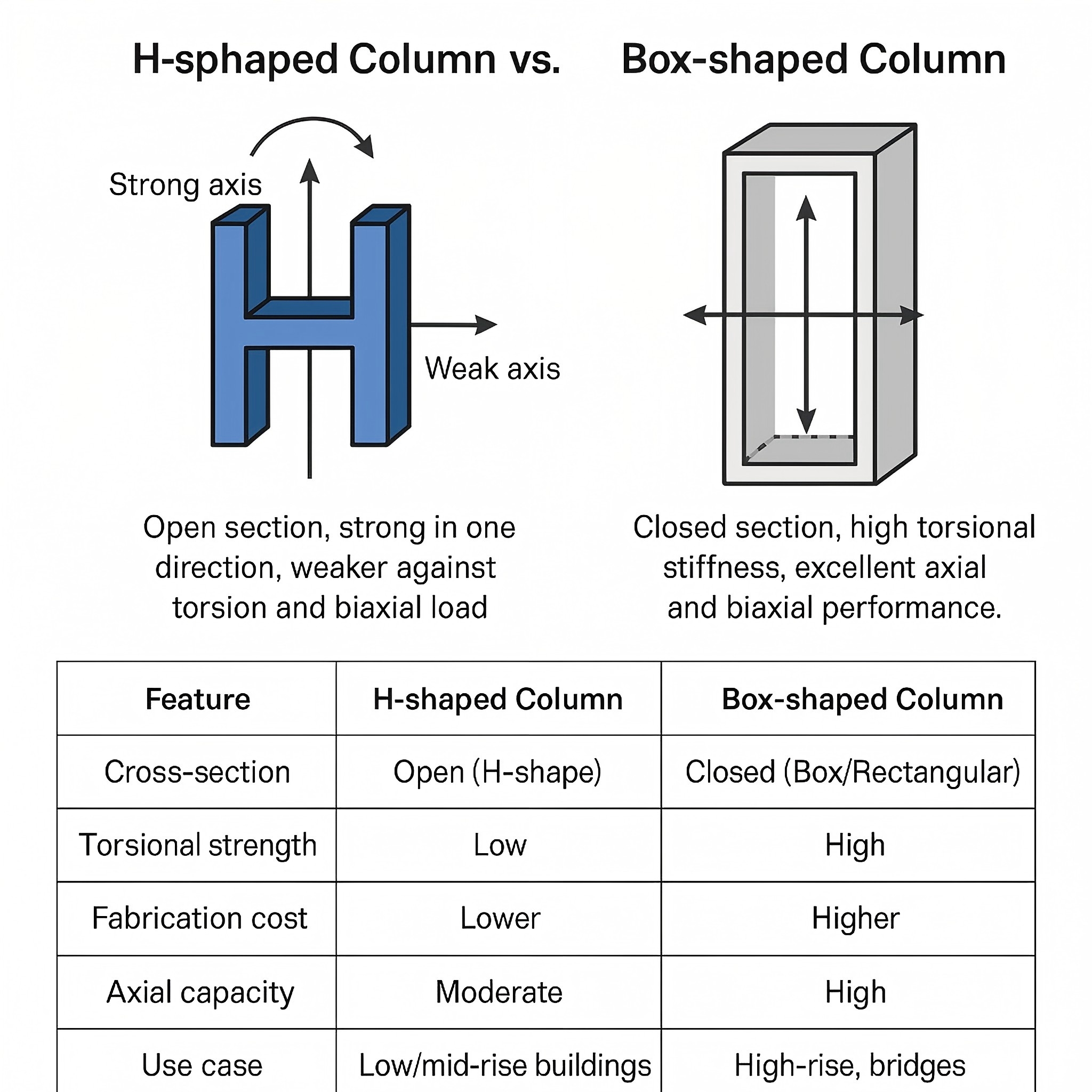

An H-shaped steel column is a structural member with an “H” cross-section, produced by hot rolling or welding. It offers excellent bending resistance and high section efficiency. Commonly used in industrial plants, multi-story frames, and steel residential buildings, its advantages include ease of construction and lower cost. H-shaped columns are often chosen for scenarios with lower axial loads and minimal section size requirements. In low- to mid-rise steel structures, they are widely used due to their strong cost-effectiveness.

Box-shaped column:

A box-shaped column consists of a closed section formed by welding four steel plates together. It has high stiffness and strong torsional resistance, making it ideal for high-rise buildings, bridges, or large-span structures where stability is critical. Concrete can also be filled inside to further enhance load-bearing capacity and fire resistance. Box-shaped columns are commonly used in heavy-load areas, complex joints, or architectural designs with special appearance requirements.

Technical Analysis: Structural Performance Characteristics of H-shaped vs. Box-shaped Columns!!

Structural Load-Bearing Capacity Analysis:

Box-shaped columns have similar stiffness in both directions due to their closed cross-section, offering better stability and higher axial load capacity. H-shaped columns, with lower stiffness along the weak axis, are more prone to buckling but still perform well under normal loads. For extremely high axial forces, box-shaped columns are preferred, especially in high-rise structures.

Flexural Stiffness:

The H beam concentrates material primarily in its top and bottom flanges, providing excellent bending resistance along its strong axis. In comparison, box columns offer balanced stiffness in both principal axes but are less efficient in single-axis bending than equally weighted H beams. Engineering experience indicates H beams typically achieve required stiffness with lighter sections, making lateral deformation easier to control.

Torsional resistance:

H beams concentrate material primarily in the top and bottom flanges, providing superior bending resistance along the strong axis and efficiently resisting unidirectional bending moments. In contrast, box columns, composed of plates on all four sides, offer balanced stiffness in both principal directions but generally have lower uniaxial bending efficiency compared to equally weighted H beams. Engineering practice indicates that H beams typically meet stiffness requirements with less material and provide improved control over lateral deformations, such as inter-story drift.

Construction Adaptability:

H beams have a simpler structure, comprising a web and two flanges, typically joined by just four longitudinal welds. Exposed seams facilitate double-sided welding and easier internal anti-corrosion coating and maintenance.

In contrast, box columns, formed from four welded steel plates, involve complex corner welds that complicate double-sided welding and quality control. Their closed sections hinder internal anti-corrosion treatment and corrosion inspection. Beam-to-column connections also require extended or perforated plates, increasing on-site complexity compared to simpler flange connections in H beams.

Cost Comparison: Material Utilisation, Fabrication Processes, and Transportation & Construction Costs

Material efficiency:

From an economic perspective, H beams typically meet structural strength requirements with less steel. Concentrating material in the flanges at the periphery significantly enhances bending efficiency, reducing the steel required per unit load capacity or stiffness. In contrast, box columns, involving all four sides in load-bearing, often necessitate thicker plates and additional stiffeners for stability, thus increasing steel usage and weight to achieve equivalent strength and stiffness. Generally, under identical loading conditions, box columns have greater cross-sectional areas and weights than H beams, directly impacting their overall cost.

Fabrication cost:

H beams are simpler to fabricate, requiring fewer welds and easier access for assembly and inspection. Their open-section design reduces welding time and labour, making mass production more efficient.

In contrast, box columns involve more complex welding—especially corner joints—which are harder to access and require higher precision and quality control. This increases labor time, inspection difficulty, and overall fabrication cost.

Transportation and Construction Cost:

H beams have narrower sections and lighter weight, making them easier and more economical to transport without exceeding width or weight limits. On-site lifting and assembly are simpler, and standardized H beam components support efficient prefabrication and fast installation.

In contrast, box columns are bulkier and heavier, often requiring special transport due to oversize dimensions. Heavier lifting equipment is needed on-site, increasing machinery costs. Their closed sections require external plates for beam-column connections, leading to more complex installation procedures and higher labor input. Overall, for the same structural function, box columns typically incur higher total costs from fabrication to installation compared to conventional H beams.

Engineering Practice: Column Type Selection in Typical Projects

Low- to Mid-Rise Industrial Buildings and Multi-Story Structures: H beams are typically the first choice for columns for industrial plants and multi-story steel frame buildings using portal frames or steel frameworks. They offer a cost-effective solution to meet load-bearing and stiffness requirements and allow easy connections to steel beams, crane girders, and other components, making them ideal for large-span workshops and warehouses. Given the relatively moderate axial loads and lateral forces in such structures, the weaker axis of H beams can be compensated by adding bracing between columns, without the need for more expensive box columns. Only in rare cases, such as buildings supporting large overhead cranes with significant torsional loads or requiring exceptional lateral stiffness, are box columns considered to enhance structural stability.

High-Rise and Super-Tall Buildings:Steel high-rises face heavy axial loads, bending moments, and seismic forces. To ensure strength and stiffness, box columns or steel tube columns are commonly used as main vertical members. The closed box section offers strong biaxial bending stiffness and excellent torsional resistance, ideal for resisting wind and seismic loads.Many super-tall buildings use large box or cylindrical steel columns, sometimes filled with concrete for composite action, providing high axial and lateral load capacity. Overall, box columns are widely adopted in skyscrapers for their superior load-bearing and stiffness performance.

Long-Span Structures:In stadiums, exhibition halls, and hangars, columns must handle large roof loads and heights. Box or tubular columns are often used for their high stiffness, torsional resistance, and clean appearance—ideal for exposed structures under wind or uneven loads. For cost-saving, some projects still use H beams with added bracing. Overall, box columns are more common in long-span buildings requiring both stability and aesthetics.

Conclusion & Recommendation: Column Selection Principles

Column selection should balance structural performance, cost-efficiency, and construction practicality.

-

H beams are ideal for low- to mid-rise buildings and industrial structures due to their material efficiency, ease of fabrication, and low cost.

-

Box columns are preferred in high-rise, long-span, or architecturally exposed structures for their high stiffness, torsional resistance, and clean appearance.

Recommendation: Choose H beams when economy and speed are priorities; select box columns when stability, torsion resistance, or aesthetics are critical.

Build Your Steel Structure with HHY Steel Structure

At HHY Steel Structure, we design and customize steel buildings tailored to your needs, ensuring high performance and compliance with international quality standards.

For a quotation, please fill out the form below or contact us at info@hhysteelstructure.com. Our team will get back to you promptly.