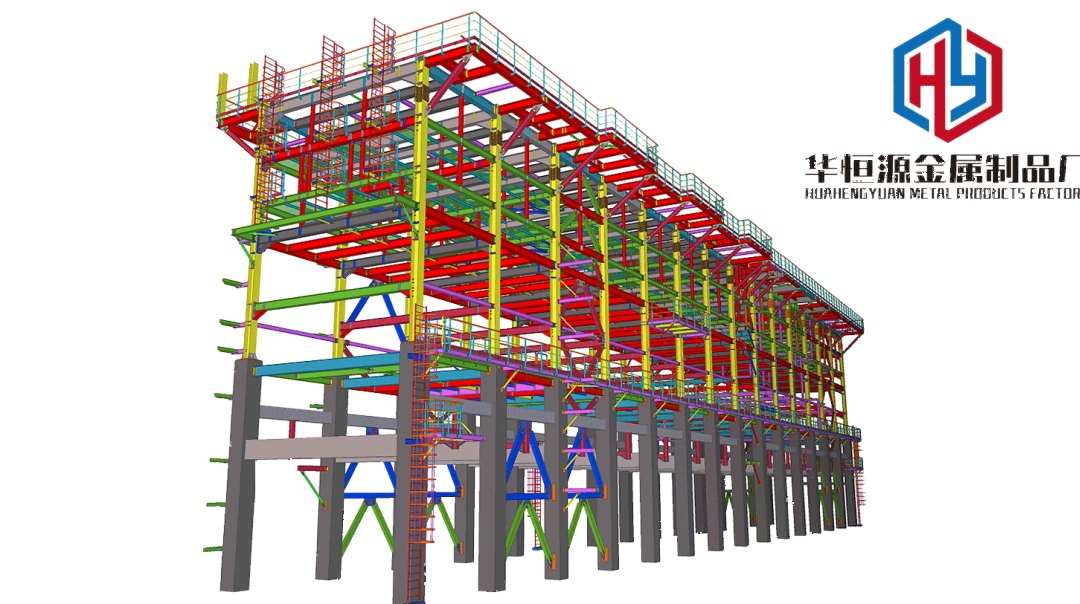

With the rapid development of the construction industry, the design of steel structures has fully entered the digital era. Today, professional software such as Tekla, YJK, CAD and PKPM is widely used to perform structural modeling, mechanical analysis, overall system design, and detailed drawing preparation—covering the entire workflow from force calculations to connection detailing and fabrication drawings. Supported by advanced technology, the design process has become more accurate, efficient, and standardised, significantly reducing human errors and enhancing the overall safety, performance, and constructability of steel structures. As a result, modern steel structure design is evolving toward greater intelligence, visualisation, and automation, setting a new benchmark for the industry.

Process of Design

1. Site Survey to Confirm Whether Steel Structure Is Suitable

The first step in a steel building structure project is a site survey to evaluate ground conditions, space, and environmental factors. This helps determine if the project can benefit from a steel frame building, especially when large spans or heavy loads are required. Basic structural modeling and analysis is also performed to predict how the structure will behave under wind, seismic, and foundation conditions. A proper site survey ensures the feasibility of the steel structure design and provides accurate data for the following steel construction process.

Framework of China Future Technology Tower

2. Selecting the Proper Structural System and Layout

During the arrangement phase of steel structure design, engineers must develop a comprehensive layout that reflects both the overall system and its subsystems. Design concepts are based on structural mechanisms, technical experience, and the specific requirements of the building. A proper steel structure arrangement must consider load paths, span length, functional needs, and potential risks.

On-site assessment of the Saudi Arabia project

Engineers analyse differences in structural behavior—for example, roof areas that withstand heavy rain must be designed with the correct curvature and slope, while high-rise buildings may require a combined steel–concrete system for added stiffness and stability. Through structural modeling and analysis, designers adjust beam directions, column spacing, and support systems to ensure efficient force distribution. A well-planned arrangement creates a stable, safe, and functional steel frame building, forming the foundation for a smooth steel construction process.

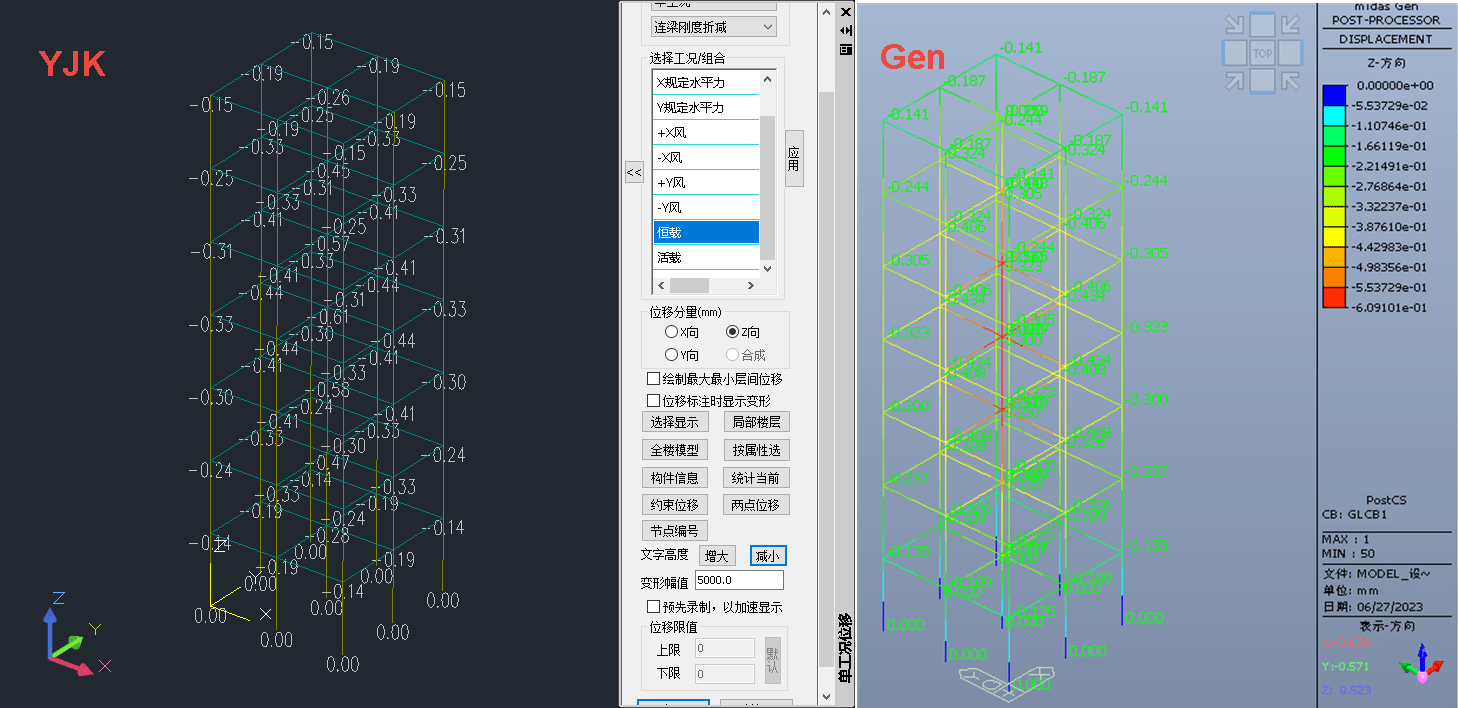

3. Preliminary Design and Structural Modeling

At the start of the design process, the engineering team communicates closely with the client to identify any special structural requirements or unique ideas they wish to incorporate into the steel structure design. Based on this information, the designers analyze local soil conditions as well as wind and snow characteristics to create an initial scheme for the steel building structure. Using YJK for comprehensive structural modeling and analysis, engineers develop the overall model—including stress models, wind and snow load models, and ground-support models. Components that fail to meet design criteria are adjusted repeatedly until all nodes and members appear in green, indicating full compliance. Once the model is validated, preliminary drawings are prepared and delivered to the client for review. Through multiple rounds of communication and refinement, the design is finalized to fully meet both technical requirements and the client’s expectations.

Structural Model Analysis

4. Technical Verification and Safety Checks

Once the preliminary model and drawings are completed, a comprehensive technical verification is carried out to ensure that the steel building structure meets all safety and performance requirements. This includes checking structural stability, lateral displacement, vibration control, and overall load-bearing capacity under wind, snow, and seismic forces. The design team performs detailed calculations on beams, columns, bracing members, and key steel structure connections, ensuring full compliance with national and international standards such as GB, EN, or ASTM specifications. Any components that do not meet safety criteria are redesigned and rechecked until the entire structure satisfies all engineering requirements.

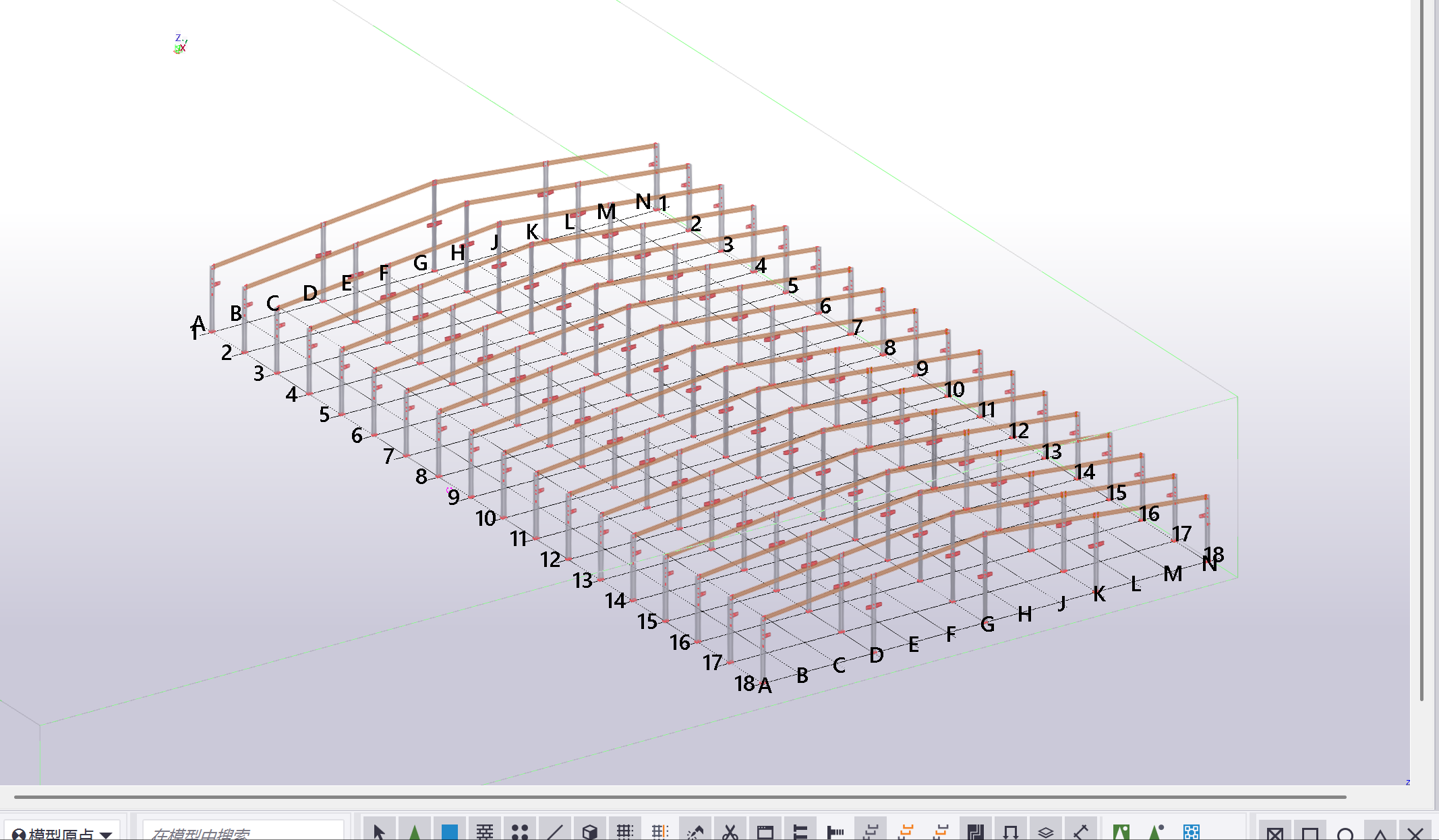

5.Connection Design and Structural Detailing

Connection design is one of the most critical stages in steel structure engineering, as it determines the efficiency and safety of force transfer between structural members. At this stage, engineers not only finalize the steel beam and column design but also ensure that the cross-sections, reinforcement plates, and load paths work seamlessly with the connection layout. Rigid connections, hinged connections, and semi-rigid connections are selected based on the building’s functional needs and structural behavior.

Construction drawing drafting stage

Detailed analysis is performed on bolt groups, weld thickness, end-plate dimensions, stiffeners, continuity plates, and joint plate arrangements to ensure every component meets the required capacity. Special attention is given to high-stress areas such as column bases, roof bracing joints, truss nodes, and beam-to-column moment connections. Accurate detailing in both member design and connection design ensures that the entire steel construction process proceeds smoothly and that on-site installation can be completed without errors, rework, or delays.

Many people may assume that this stage repeats the analysis already performed in YJK, but it is important to emphasize that YJK is primarily used for overall structural modeling and global force analysis. While it provides reliable results for the building’s overall behavior, it does not deliver the level of precision required for detailed components. Therefore, once the full structural detailing and shop drawings are generated, a second round of reasonableness checks and verification is essential. This includes reviewing beam-column details, connection geometry, plate sizes, bolt arrangements, and weld configurations. Any inconsistency or insufficient capacity identified during this stage is corrected and optimized to ensure that the final design is accurate, safe, and fully constructible.

6. Detailed Drawing Production, Approval, and Coordination

After the structural model is confirmed, the design team uses TEKLA to produce detailed drawings, including component details, connection details, assembly drawings, anchor bolt layouts, BOM, fabrication drawings, and installation drawings. These drawings are then reviewed and signed by the chief engineer, department director, and key designers to ensure they meet all standards.

Once approved, the factory rechecks fabrication and installation drawings before starting production. During manufacturing, any issues—such as material deviations or tolerance conflicts—are immediately reported to the design team for quick adjustment. Before installation, key dimensions are verified on site to match the drawings. This coordinated process ensures the steel frame building is fabricated accurately, delivered on time, and installed safely.

If you need a professional steel structure service provider that can handle design, fabrication, and installation in one complete package

——choose HHY Steel Structure for a reliable, efficient, and fully integrated solution.