In today’s construction and infrastructure landscape, structural steelwork plays an essential role. Whether in warehouses, high-rise buildings, or transport terminals, structural steel provides the backbone for safe, strong, and long-lasting structures.

Composed mainly of iron, carbon, and alloying elements, structural steel is valued for its strength, flexibility, and resistance to deformation. But beyond the metal itself, steelwork refers to the entire process of shaping, assembling, and preparing steel components for actual use in construction.

This article breaks down the essentials of structural steelwork: what it means, how it’s produced and fabricated, and where it’s used across different industries.

Understanding Structural Steelwork

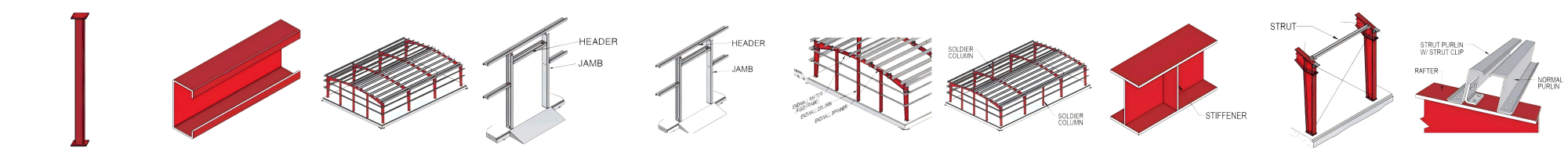

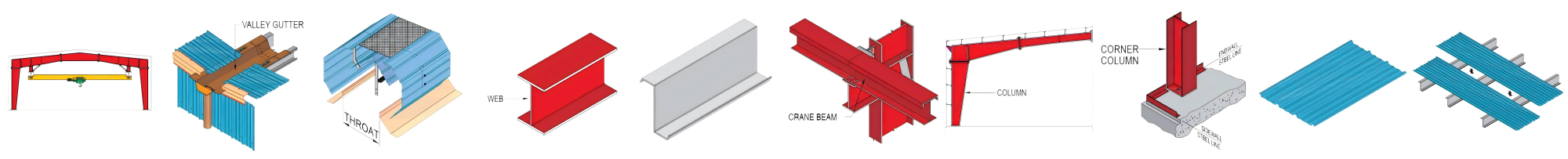

Structural steelwork involves the creation of steel elements that form part of a building’s load-bearing system. These elements—beams, columns, frames, trusses—are fabricated to meet the precise demands of a structure’s design.

What makes structural steel so widely used is its combination of strength and adaptability. It offers the capacity to carry substantial loads while remaining light enough for efficient transport and installation. This makes it ideal for projects requiring both performance and speed

How Structural Steel Is Manufactured

Steel manufacturing begins with refined iron ore, which is processed in high-temperature furnaces. Impurities are removed, and the resulting molten metal is then alloyed with specific elements like manganese or carbon to modify properties such as hardness and elasticity.

Several types of steel are commonly used in structural applications:

- Carbon Steel: Versatile and cost-effective, used widely for beams and frames.

- Galvanized Steel: Coated with zinc to improve corrosion resistance, especially useful in marine or humid environments.

- Alloy Steel: Enhanced with elements like chromium or nickel for specialized industrial performance.

Fabrication: From Raw Material to Building Component

Once steel has been produced, structural steelwork fabrication turns raw materials into functional components ready for site installation. This multi-step process includes:

- Detailing and Design: Engineers produce precise models based on building requirements.

- Cutting and Forming: Steel is shaped using tools like plasma cutters, saws, or CNC machines.

- Assembly: Sections are joined by welding or bolting into complete structures.

- Finishing: Surfaces are treated—galvanized, painted, or coated—to enhance durability.

- Delivery: Completed elements are transported to the construction site for erection.

Fabrication must follow national and international standards to ensure load capacity, fire resistance, and dimensional accuracy.

Common Types of Structural Steel Components

Structural steel comes in various shapes, each with specific structural uses:

- I-Beams & Universal Beams – For horizontal support in floors and ceilings.

- Rectangular and Square Hollow Sections – Common in columns and frameworks.

- Angle Sections (L-shapes) – Used in bracing and light frameworks.

- Channels and Flats – Useful in platforms, secondary framing, and edge finishes.

- Tubular Sections – Ideal for projects needing strength in multiple axes.

Each profile is chosen based on the building’s load demands and architectural design.

Industries That Depend on Structural Steelwork

The versatility of structural steelwork makes it a core material in numerous sectors:

- Construction – Structural frames, mezzanines, roof trusses, and bridges.

- Energy – Used in transmission towers, pipeline supports, and turbine structures.

- Manufacturing – Factory mezzanines, platforms, industrial stairs, and supports.

- Transport & Logistics – From rail platforms to airport hangars.

- Shipbuilding – Frameworks for hulls, decks, and internal ship structures.

- Automotive & Aerospace – Structural frames, reinforcements, and assembly lines.

- Mining – Steel conveyor systems, support towers, and protective equipment.

Conclusion

Structural steelwork isn’t just about metal—it’s about precision, performance, and reliability. From the manufacturing process to final on-site assembly, every step is engineered to meet modern construction demands. If you’re building for scale, speed, or durability, structural steelwork offers a proven solution that continues to shape the infrastructure of tomorrow.