In modern construction projects, especially in industrial, commercial, and infrastructure developments, structural steel and plate fabrication play a vital role. It ensures that the building framework is durable, safe, and optimised for efficiency. This article explores the processes involved in structural steel and plate fabrication, including the standard procedures and their diverse range of applications.

1. What is Structural Steel and Plate Fabrication?

Structural steel and plate fabrication refers to the process of cutting, shaping, assembling, and finishing steel components such as beams, columns, and trusses based on engineering designs. These components serve as the core load-bearing elements in structures ranging from factories and warehouses to airports and high-rise buildings.

The fabrication process requires strict adherence to design specifications and quality standards to ensure that the components meet structural, dimensional, and safety requirements.

2. Key Manufacturing Processes

2.1 Cutting

Steel plates and sections are cut into specific dimensions using technologies such as:

-

Laser cutting

-

Plasma cutting

-

Oxy-fuel cutting

-

Band saws and shearing machines

2.2 Forming and Punching

After cutting, steel parts may be bent or shaped using press brakes or rollers. Punching machines are used to create bolt holes and slots necessary for later assembly.

2.3 Welding

Temporary assembled components are welded using manual or automated welding machines. Common methods include MIG, TIG, and submerged arc welding. Post-weld inspections (visual, ultrasonic, magnetic particle) ensure joint integrity.

2.4 Heat Distortion Adjustment

Welding may cause thermal deformation. Precision straightening is done to ensure the flatness and alignment of each component before final assembly.

2.5 Reinforcement

Stiffeners, cleats, and gussets are added to strengthen components in high-stress areas. Reinforcement is typically done through additional welding or bolting.

2.6 Surface Treatment

Before coating, steel is cleaned using shot blasting or sandblasting to remove scale, rust, and oil. This improves paint adhesion and corrosion resistance.

2.7 Coating

To protect against environmental damage, steel components are coated with:

-

Anti-corrosion primer

-

Fire-resistant paint (if required)

-

Topcoat in custom colors per project needs

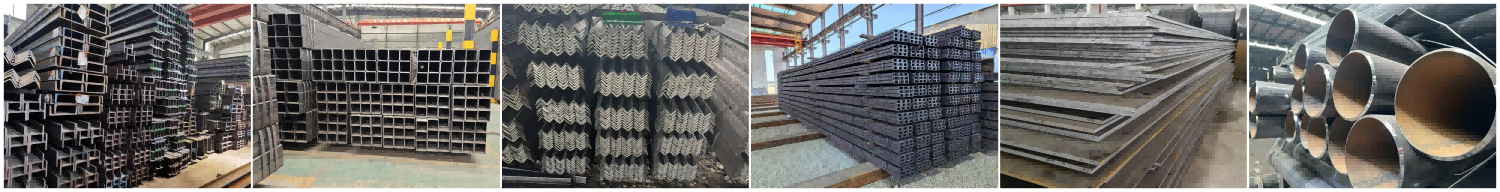

3. Common Structural Steel Components

-

Flat bars and plates

Each component serves different structural purposes, selected according to project design and load requirements.

4. Applications of Structural Steel Fabrication

Structural steel is used across multiple sectors:

-

Industrial buildings: factories, workshops, production halls

-

Commercial: malls, parking structures, office complexes

-

Infrastructure: bridges, towers, transportation terminals

-

Energy: power plant platforms, turbine frames, transmission towers

5. Quality Standards and Certifications

Reliable steel fabrication adheres to international standards such as:

-

ASTM (American Society for Testing and Materials)

-

EN (European Norms)

-

JIS (Japanese Industrial Standards)

-

ISO 9001:2015 for quality management

Welding inspections and quality tests include:

-

Ultrasonic testing (UT)

-

Magnetic particle inspection (MPI)

-

Dimensional verification

6. Why Choose HHY Steel Group?

Our steel fabrication services are backed by:

-

Decades of fabrication experience

-

State-of-the-art machinery (laser cutters, CNC drills, automated welding)

-

Skilled engineers and certified welders

-

Strict in-house quality control

-

Proven international projects in Southeast Asia, Europe, and South America

We source certified raw materials and offer full traceability, from mill test certificates to final shipment. Our prefabricated steel solutions reduce onsite labor and improve construction timelines.

7. Conclusion

Structural steel and plate fabrication is the backbone of modern, high-performance building frameworks. With precision manufacturing, strict standards, and quality coatings, fabricated steel ensures long-term safety, efficiency, and versatility. Whether your project involves an industrial complex or a customized warehouse, choosing expert steel fabrication partners is key to success.

Contact our team today for design consultation, material selection, and fabrication solutions tailored to your project needs.