Steel structure – Rising star in the Steel industry

If you’re aiming for the most cost-effective construction option, it’s essential to evaluate both the upfront costs and the long-term savings that come with the choice of materials and construction methods. Steel structure, made from high-quality structural steel, offer excellent value over time due to their durability and low maintenance needs. With the added advantage of prefabrication, which reduces on-site labour and construction time, steel is especially ideal for industrial buildings, where efficiency, scalability, and cost savings are critical factors in project success.

What is steel structure?

Steel structure is an advanced form of construction that utilizes high-strength structural steel to create stable and durable frameworks. Unlike traditional materials like concrete and timber, steel offers superior strength-to-weight ratios, making it ideal for buildings that require large spans and open spaces without excessive support columns. The inherent flexibility of steel also makes it highly resistant to dynamic forces, such as wind or earthquakes, providing added safety and longevity to the structure.

In addition to its strength, the use of prefabrication in steel construction significantly enhances efficiency. Components are manufactured in a controlled factory environment, ensuring precise dimensions and quality control before being transported to the site for quick assembly. This process not only reduces construction time but also minimizes on-site waste, making steel structures particularly beneficial for industrial buildings, where rapid and cost-effective construction is essential.

|

|

|

Shentong Logistics Warehouse |

Photovoltaic Manufacturer Warehouse |

Corporation With (CECC) |

*If you’re looking for competitive pricing and high-quality steel structures, contact us at info@hhysteelstructure.com. We specialize in using premium structural steel to deliver efficient, durable solutions for your projects.

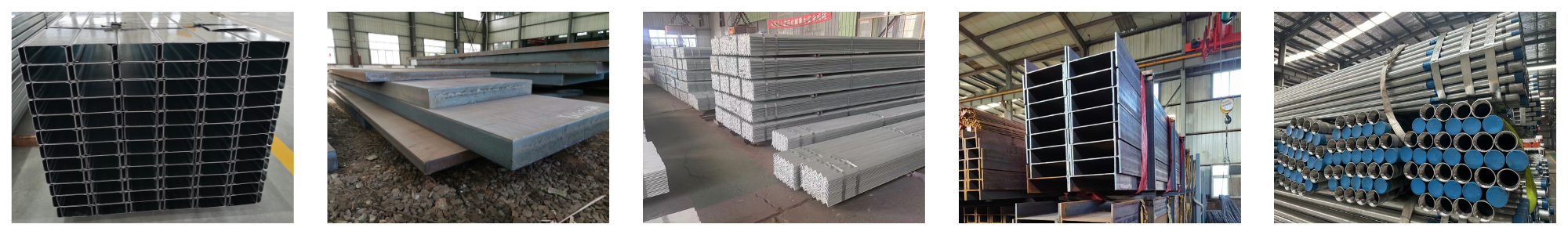

Structural steel is a type of construction material designed to meet the unique specifications of each project. It is manufactured in various shapes and sizes, using processes such as hot or cold rolling, or by welding flat or curved plates together. Typical forms include channels, plates, angles, I-beams, and HSS (Hollow Structural Sections), all selected to suit specific structural requirements.

The flexibility of structural steel allows it to be customized for a wide range of applications, from industrial buildings to large-scale infrastructure projects. Its strength, versatility, and ability to withstand dynamic forces like wind and earthquakes make it an ideal choice for modern construction projects.

Structural Classification & System Definitions

Primary Framing Systems

Rigid Frame Structures

Steel beams (ASTM A992) and columns (A500 Gr. C) form moment-resisting skeletons for industrial/warehouse buildings, achieving 30–60m clear spans with bolted end-plate connections.

Space Grid Structures

Triangular-latticed steel nodes (EN 1090-2 compliant) create lightweight roofs for airports/stadiums, enabling 150m+ column-free spaces with 40% material reduction vs solid sections.

Long-Span & Specialized Systems

Prestressed Steel Structures

Post-tensioned high-strength cables (1,860 MPa grade) counteract deflection in bridge girders and hangar roofs, enhancing load capacity by 25% while minimizing depth.

Truss Systems

Warren-type steel trusses with hollow section chords (SHS/RHS) optimize roof/bridge support, reducing dead loads by 35% through strategic member triangulation.

Arch Systems

Curved steel ribs (fabricated per AISC 303-16) transfer vertical loads laterally, ideal for aircraft hangars (90m spans) and signature bridges with ≤3% slope tolerance.

Advanced Bridge Typologies

| Type | Key Characteristics |

|---|---|

| Arch Bridges | Thrust-optimized steel arches (tied or through configurations) for 200–500m river crossings, using weathering steel (A588) to eliminate painting. |

| Cable-Stayed | Mono/twin pylons with locked-coil steel cables (ASTM A416) enabling 1,000m+ spans, vibration-damped with PE-sheathed strands. |

| Suspension | Main cables (parallel wire bundles) and orthotropic steel decks for 2km+ spans, achieving 8:1 span-to-depth ratios. |

| Truss Bridges | Pratt/Howe truss configurations with galvanized chord members (G90 coating) for heavy rail spans (50–150m). |

| Beam Bridges | Plate girder systems (welded A572 Gr.50) with composite concrete decks for highway viaducts (20–50m spans). |

*Send an email to contact us at info@hhysteelstructure.com. Get your precise quote!

Competitive Advantages of Our Steel Structure Solutions

Cost Efficiency with Structural Steel

Our prefabricated steel structure systems reduce project costs by 25-40% with optimized material usage (ASTM A913 Gr.65). Prefabrication minimizes on-site labor by 60%, while reducing foundation requirements offers extra savings for industrial buildings.

Architectural Flexibility

Design column-free spaces up to 80m using cantilevered steel frames and custom-curved HSS members. Combine energy-efficient glazing with steel facades for industrial buildings that offer both functionality and striking aesthetics.

Precision in Prefabrication

CNC-cut components, meeting ISO 9013 standards, arrive with +/-1.5mm tolerance. This allows bolt-up assembly 3x faster than traditional methods, streamlining construction of steel structures and ensuring seamless integration with MEP systems.

Durability of Structural Steel

Hot-dip galvanized structural steel (ISO 1461) resists Category 5 hurricanes, 9.0M seismic events (AISC 341 compliant), and provides over 50 years of corrosion protection—outlasting timber by 400% in humid environments, perfect for industrial buildings.

Sustainable Expansion

Achieve LEED Platinum certification with 92% recycled steel content and solar-ready roof trusses. Our modular steel structure systems allow easy expansion of industrial buildings without downtime—simply unbolt and extend.

Build a Steel Structure Building with HHY Steel Structure

At HHY Steel Structure, we design custom steel buildings tailored to your needs, ensuring high performance and international quality standards.

For a quote, fill out the form below or email info@hhysteelstructure.com. Our team will contact you promptly.