Structural Steel is widely used in industrial buildings and warehouses, making the protection of the Steel Structure Surface a critical factor for long-term durability. Before any coating is applied, Shot Blasting is commonly used to clean and prepare the steel, ensuring proper adhesion and enhanced corrosion resistance. For projects requiring stronger anti-corrosion performance, Galvanizing provides a durable zinc layer, while epoxy paint offers excellent chemical and mechanical resistance for heavy-duty applications. Painting remains a flexible and cost-effective option for many general-purpose steel structures. This article introduces these core surface treatment methods and explains how they enhance the performance and service life of modern Steel Structure systems.

I.Shot Blasting

Shot Blasting is one of the most essential processes in steel structure surface treatment. By propelling high-speed steel shots onto the metal surface, this method removes rust, mill scale, welding residues, and contaminants, while also creating a uniform surface profile. This provides the ideal foundation for subsequent coatings such as galvanizing, epoxy paint, and industrial painting.

Shot Blasting Process

Equipment inspection→Loading steel components→High-speed blasting inside the machine→Air cleaning to remove steel shots→Visual and instrument inspection→Immediate priming to avoid flash rust

International Standards for Shot Blasting

According to ISO 8501-1:

| Grade | Name | Description |

| Sa 1 | Light Blasting | Light cleaning |

| Sa 2 | Thorough Blasting | Most contaminants removed |

| Sa 2.5 | Very Thorough Blasting | Industry standard; near white metal |

| Sa 3 | White Metal Blast | Completely clean, white metal |

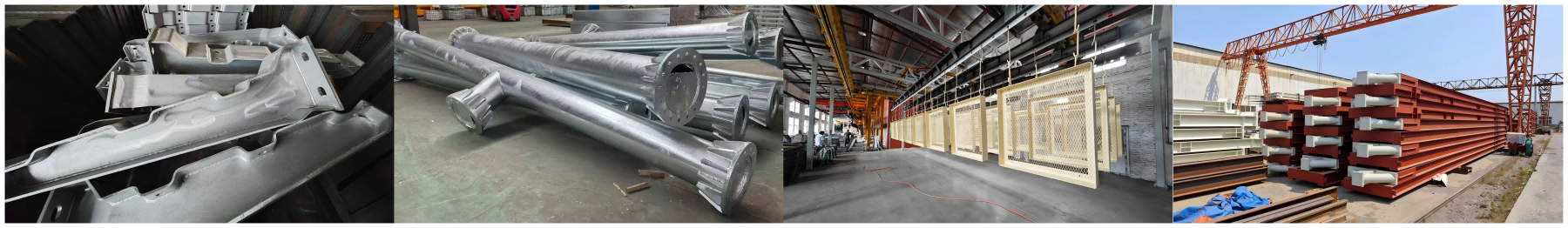

II.Galvanizing

Galvanizing is a highly effective corrosion-protection method in which a layer of zinc is applied to the surface of steel. The zinc coating acts as both a barrier and a sacrificial layer, protecting the steel from moisture, chemicals, and atmospheric corrosion. As one of the most durable and maintenance-free anti-corrosion systems for structural steel, galvanizing is widely used in industrial buildings, warehouses, outdoor structures, bridges, and coastal environments.

Hot Dip Galvanising Process

Degreasing (Removes oil and contaminants)→Pickling (Removes rust and mill scale)→Rinsing(Cleans the steel surface)→Fluxing(Prevents oxidation before dipping)→Galvanizing (Steel enters molten zinc to form alloy layers)→Cooling(Solidifies and stabilizes the coating)→Inspection(Zinc thickness, adhesion, uniformity)

International Standards for Hot Dip Galvanising

According to ISO 1461 / ASTM A123:

| Item | ZD (µm) | Standard | Life Years | Application |

|---|---|---|---|---|

| Light steel components | 40–60 µm | ISO 1461 / ASTM A123 | 10–20 years | Indoor use, dry environments, general steel parts |

| Standard structural steel components | 60–80 µm | ISO 1461 / ASTM A123 | 20–30 years | Industrial buildings, warehouses, logistics centers |

| Heavy structural members | 80–100 µm | ISO 1461 / ASTM A123 | 25–40 years | Outdoor structures, low-to-medium corrosive environments |

| High-corrosion environments | 100–120 µm | ISO 1461 / ASTM A123 | 30–50 years | Coastal areas, chemical plants, salt-spray environments |

| Extra-thick galvanizing | 120–150 µm | Project-specific specifications | 40–60 years | Bridges, heavy-duty structures, marine facilities |

| Cold galvanizing / zinc-rich coating | 20–40 µm | ASTM A780 | 5–10 years | On-site touch-up and localized repair |

III.Epoxy Paint

Epoxy paint, also known as epoxy coating, is a heavy-duty protective coating widely used in the steel structure industry. It is made from epoxy resin and curing agents, forming a dense, hard, and strongly adhesive film after curing. Because of its excellent chemical resistance, mechanical strength, and corrosion protection, epoxy paint is one of the most reliable coating systems for industrial steel.

Epoxy Paint Process

Shot Blasting (Sa2.5) essential for adhesion→Cleaning & Dust Removal→Primer ApplicationIntermediate Coat ApplicationTop→coat Application (PU / Epoxy / Enamel)→Curing(time depends on temperature & humidity)

International Standards for Epoxy Coating

According to ISO 12944:

|

Corrosivity Category |

Environment Description | Typical Epoxy Coating System | Total Dry Film Thickness (DFT) | Life Years |

|---|---|---|---|---|

| C1 – Very Low | Indoor, dry areas | Epoxy primer + topcoat | 80–120 μm | 2-3 |

| C2 – Low | Indoor with some condensation | Epoxy primer + intermediate coat | 120–160 μm | 3-5 |

| C3 – Medium | Urban, light industrial | Epoxy zinc-rich primer + epoxy intermediate + PU topcoat | 180–240 μm | 5-15 |

| C4 – High | Industrial & coastal areas with moderate salt exposure | Epoxy zinc primer + high-build epoxy + PU topcoat | 240–320 μm | 15-25 |

| C5 – Very High | Offshore, chemical plants, heavy industrial, marine splash zones | Epoxy zinc-rich primer + high-build epoxy + IMO/PU topcoat | 320–420 μm | >25(Common 40 Years) |

| CX – Extreme | Offshore platforms, tropical marine, severe chemical exposure | Multi-layer epoxy system + specialized topcoat | 420–500+ μm | Depending on the environment |

For certain specialized projects, a combined galvanizing and epoxy coating system may be used to achieve superior corrosion protection. The process typically involves an initial round of shot blasting to improve surface adhesion, followed by hot-dip galvanizing. After galvanizing, a second round of shot blasting is performed to create an ideal surface profile for coating, and finally, an epoxy coating is applied. This multi-layer protection system significantly enhances the durability and stability of steel structures in extreme environments. However, due to its higher cost, it is generally reserved for projects exposed to severe corrosion or those requiring exceptionally high safety performance.

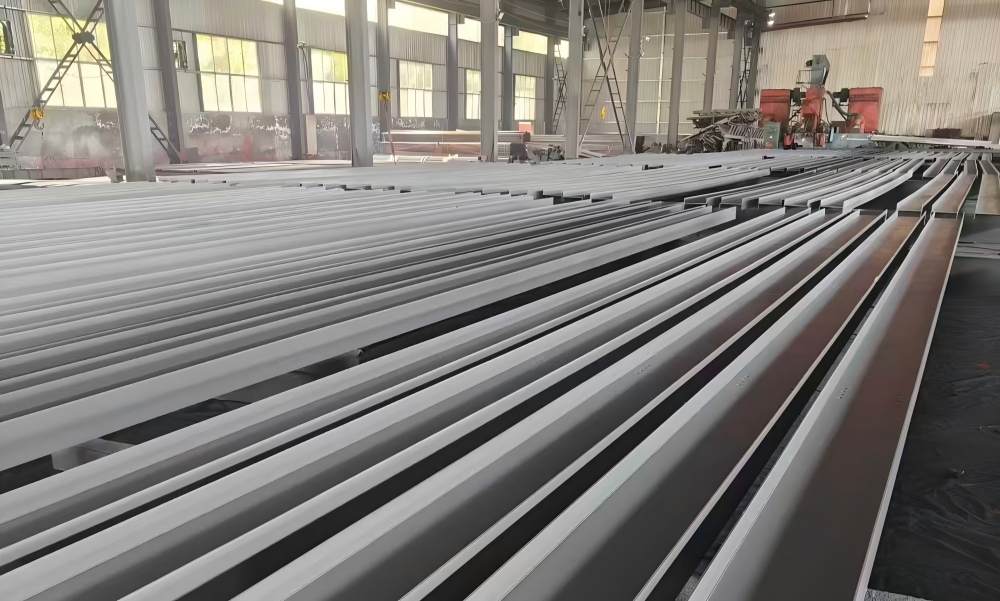

IV.Painting

Painting is one of the most common and flexible corrosion-protection methods for steel structures. By spraying coating materials onto the steel surface, painting forms a protective film that offers corrosion resistance, weather durability, and aesthetic appearance. Compared with galvanizing or heavy-duty epoxy systems, painting provides lower cost, wide color selection, and easier on-site application, making it widely used in industrial buildings, warehouses, light steel structures, and indoor installations.

Painting Process

Surface Preparation (Blasting)→ Primer Application → Intermediate Coat → Topcoat Application → Curing & Inspection

International Standards for Painting:ISO 12944

| Corrosivity Category | Environment Description | Typical Painting System | Total Dry Film Thickness (DFT) | Durability (Years) |

| C1 – Very Low | Indoor, dry environments | Primer + Topcoat | 60–100 μm | Low (L): 2–5 years |

| C2 – Low | Indoor with slight condensation | Primer + Intermediate + Topcoat | 100–140 μm | Medium (M): 5–15 years |

| C3 – Medium | Urban areas, light industrial | Epoxy primer + Intermediate + PU topcoat | 140–200 μm | High (H): 15–25 years |

| C4 – High | Industrial areas, coastal zones | Zinc-rich primer + High-build epoxy + PU topcoat | 200–260 μm | High (H): 15–25 years |

| C5 – Very High | Coastal, chemical plants, high humidity | Zinc-rich primer + Multiple epoxy layers + Marine-grade PU topcoat | 260–320 μm | Very High (VH): >25 years |

| CX – Extreme | Offshore, tropical marine, heavy chemical exposure | Multi-layer heavy-duty coating system | 320–400+ μm | Very High (VH): 25–40+ years |