Ridge Ventilation equipment in industrial steel buildings is generally classified into two main categories:

- Outlet Equipment(Today Our Point):outlet equipment ensures the removal of hot, humid, or contaminated air.

- Inlet Equipment:Inlet equipment, such as wall louvers or side openings, allows fresh air to enter the building

Among all Structural solutions, the ridge ventilator is considered indispensable, as it is strategically positioned at the roof ridge to utilize the natural stack effect, enabling continuous and efficient air circulation throughout the building. Without a properly designed ridge ventilator system, industrial facilities may face issues such as heat accumulation, condensation, and reduced indoor air quality, directly affecting both structural performance and working conditions.

Before introducing the detailed product series, it is necessary to clarify two fundamental definitions.

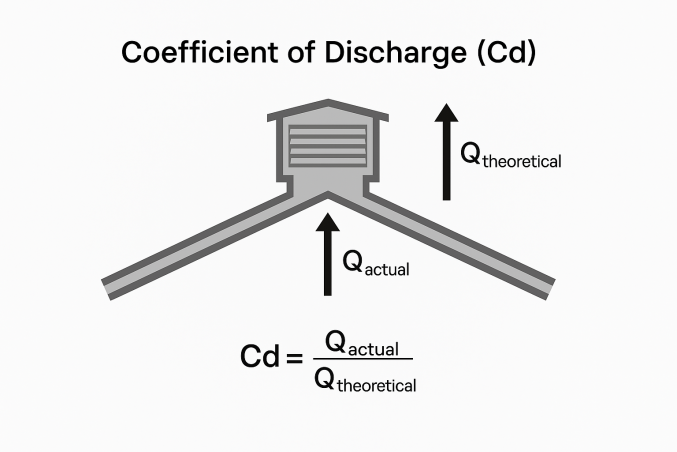

COEFFICIENT OF DISCHARGE (Cd)

- Definition:Cd is a dimensionless coefficient that measures the ratio of actual airflow through a ventilator to its theoretical maximum capacity.

- Formula:Cd = Q_actual / Q_theoretical

- Implication:A higher Cd value indicates greater efficiency in exhausting air.

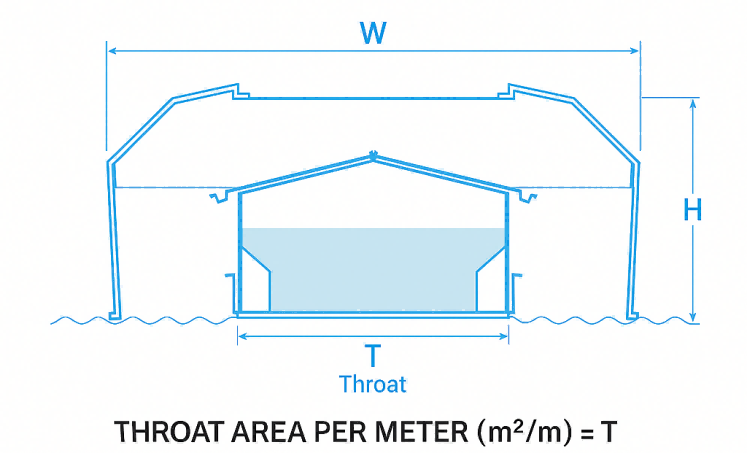

THROAT AREA

- Definition:The ventilator throat area is the effective cross-sectional opening for air discharge.

- Influence on Design

Air Volume: Larger throat → higher airflow per unit ventilator.

Load Transfer: Larger throat means heavier ventilators, increasing roof beam/purlin loading and wind resistance requirements.

Pressure Relief: Alters roof pressure distribution, helping reduce positive/negative roof pressure, but requires precise engineering.

Backdraft & Rain Ingress: If too large without guide vanes or diaphragms, risk of reverse airflow or rain penetration in strong wind.

Roof Layout:

Small throat (1/2 Series To be introduced later) → suitable for distributed, multiple-unit layout.

Large throat (3 Series To be introduced later) → suitable for centralized, modular layout, but requires higher roof stiffness.

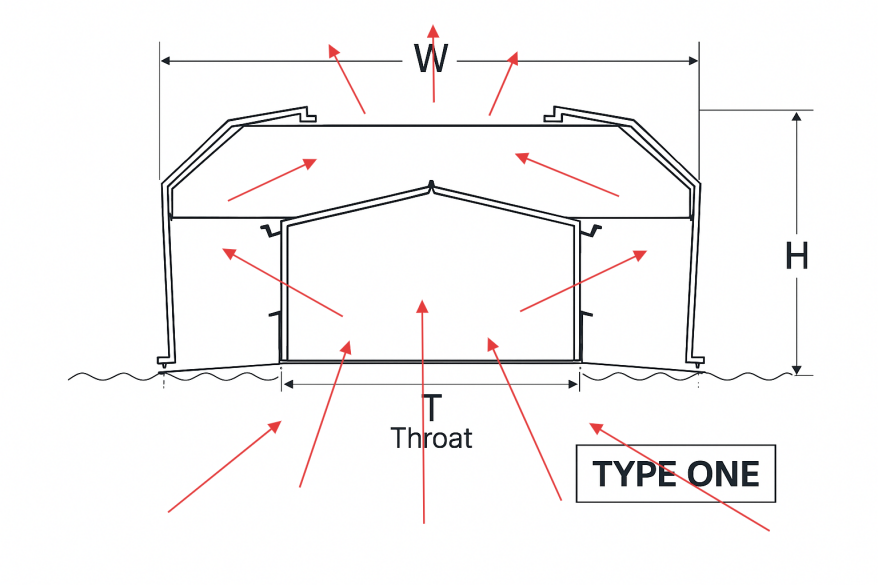

HHY Ridge Ventilator TYPE-1

Product Positioning & Applications

Positioning:Low-profile natural ventilation solution designed for buildings with low to medium heat loads.

Typical Applications:

- Warehousing & storage facilities

- Government & defence buildings

- School classrooms & auditoriums

- Sports halls & fitness centres

- Industrial workshops

- Commercial office buildings

2. Technical Performance & Certification

CSIRO Certified Testing: Passed airflow, fire resistance, rain and wind performance tests (AS2428.1 & .2 rain and wind; AS2428.4 fire; AS2428.5 Cd).

Cd Coefficient: 0.36, representing high exhaust efficiency. Designers can use this value directly for engineering calculations.

Wind & Rain Resistance: Internal guidevanes with optional dampers ensure airtightness and backflow prevention even under extreme weather conditions.

Pressure Relief: Known Cd coefficient allows engineers to optimize pressure distribution, reducing structural steel requirements and overall project cost.

3. Structural & Design Features

Low-profile appearance: Ideal for projects with strict height and architectural requirements.

Internal Guidevanes: Maintain efficient exhaust performance, even at low wind speeds.

Wind Jump Diaphragms: Create pressure differentials within the ventilator to enhance airflow efficiency, ensuring exhaust regardless of wind direction.

Drainage System: Unique design quickly expels water entry, ensuring reliability under heavy rain and storm conditions.

4. Cost & Sustainability

Passive Ventilation: No power supply required, lowering installation and operating costs.

Sustainability: Improves building energy efficiency and reduces long-term operational expenses.

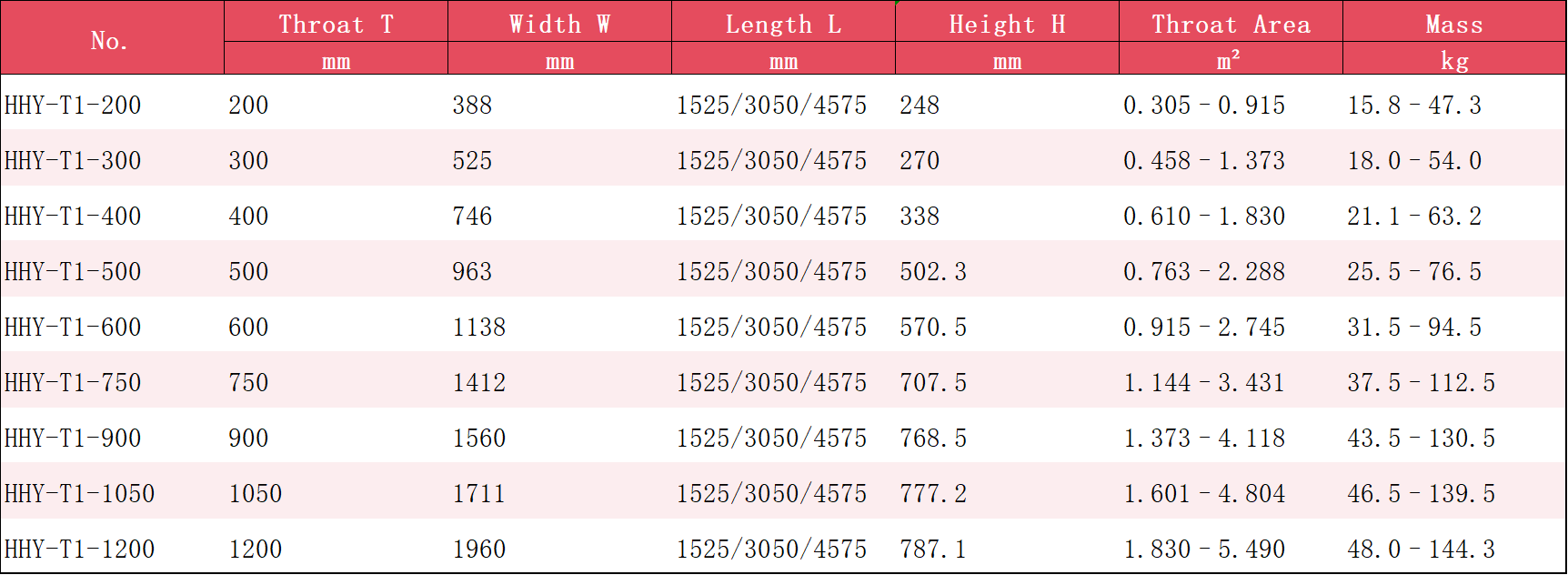

5. Specifications & Dimensions

Throat Size Range: T = 200 mm – 1200 mm, corresponding to throat areas from 0.2 to 1.2 m²/m.

Lightweight Construction: 10–32 kg/m, suitable for roofs with strict load limits or requiring lightweight solutions.

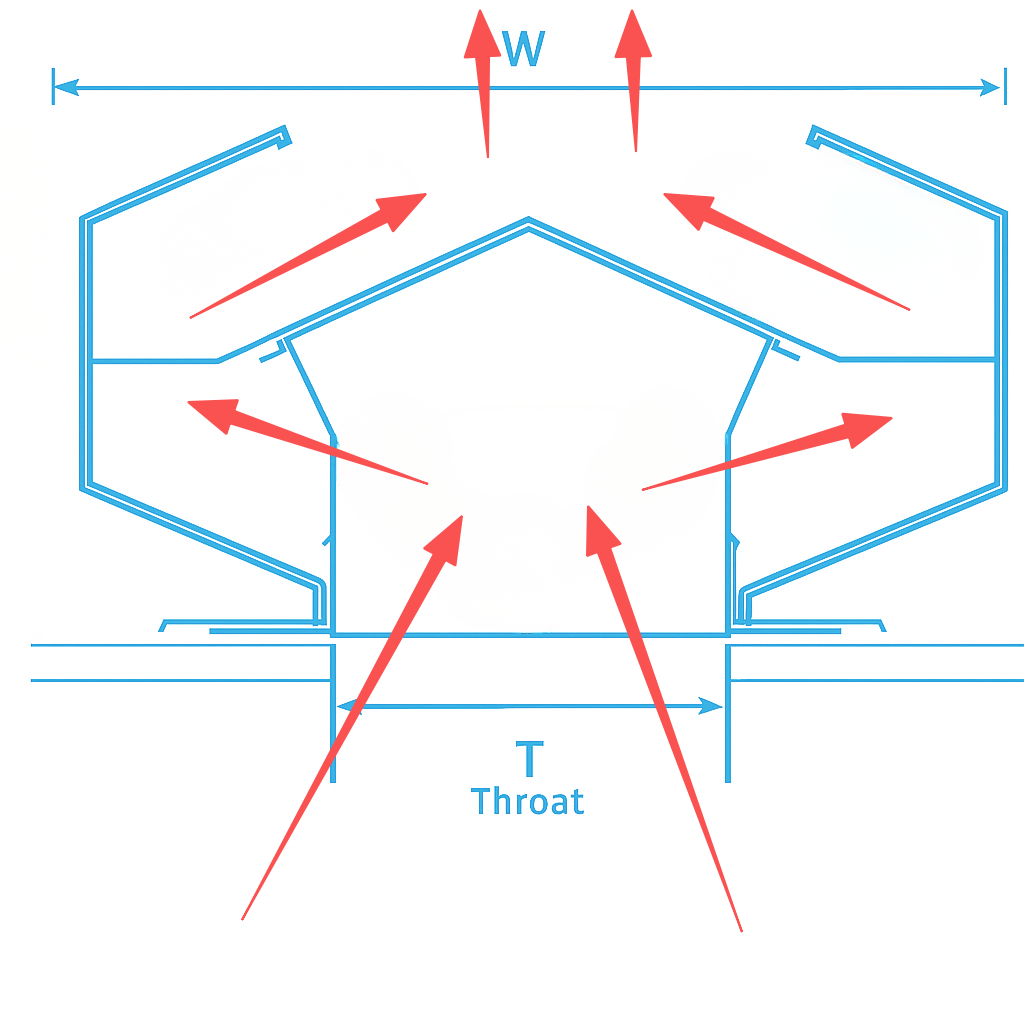

HHY Ridge Ventilator TYPE-2

1. Product Positioning & Applications

Positioning:Type 2 ventilators are designed as medium-profile, high-performance natural ventilation systems, suitable for buildings with medium to high heat loads.

Typical Applications:

- Heavy industrial workshops

- Power stations & boiler houses

- Large manufacturing plants

- Transport & logistics hubs

- Aircraft hangars

- Mining & processing facilities

2. Technical Performance & Certification

CSIRO Tested & Certified for airflow efficiency, fire resistance, rain and wind penetration (AS2428 standards).

Cd Coefficient: 0.65 – 0.75 (much higher than Type 1’s 0.36), which means more airflow per unit throat area.

Enhanced Weatherproofing: Aerodynamic hood design, combined with internal guidevanes and optional dampers, ensures high resistance against backflow and rain entry.

Structural Efficiency: Known Cd values allow engineers to precisely calculate ventilation performance, optimizing structural steel requirements and reducing costs.

3. Structural & Design Features

Medium-profile shape: Provides a balance between airflow capacity and building height limitations.

Adjustable Dampers: Can be manually or automatically controlled, allowing regulation of airflow according to building requirements.

Guidevanes & Deflectors: Improve exhaust efficiency under low wind speeds and varying wind directions.

Robust Drainage System: Directs water away from the throat area, ensuring reliability even during heavy rain or storms.

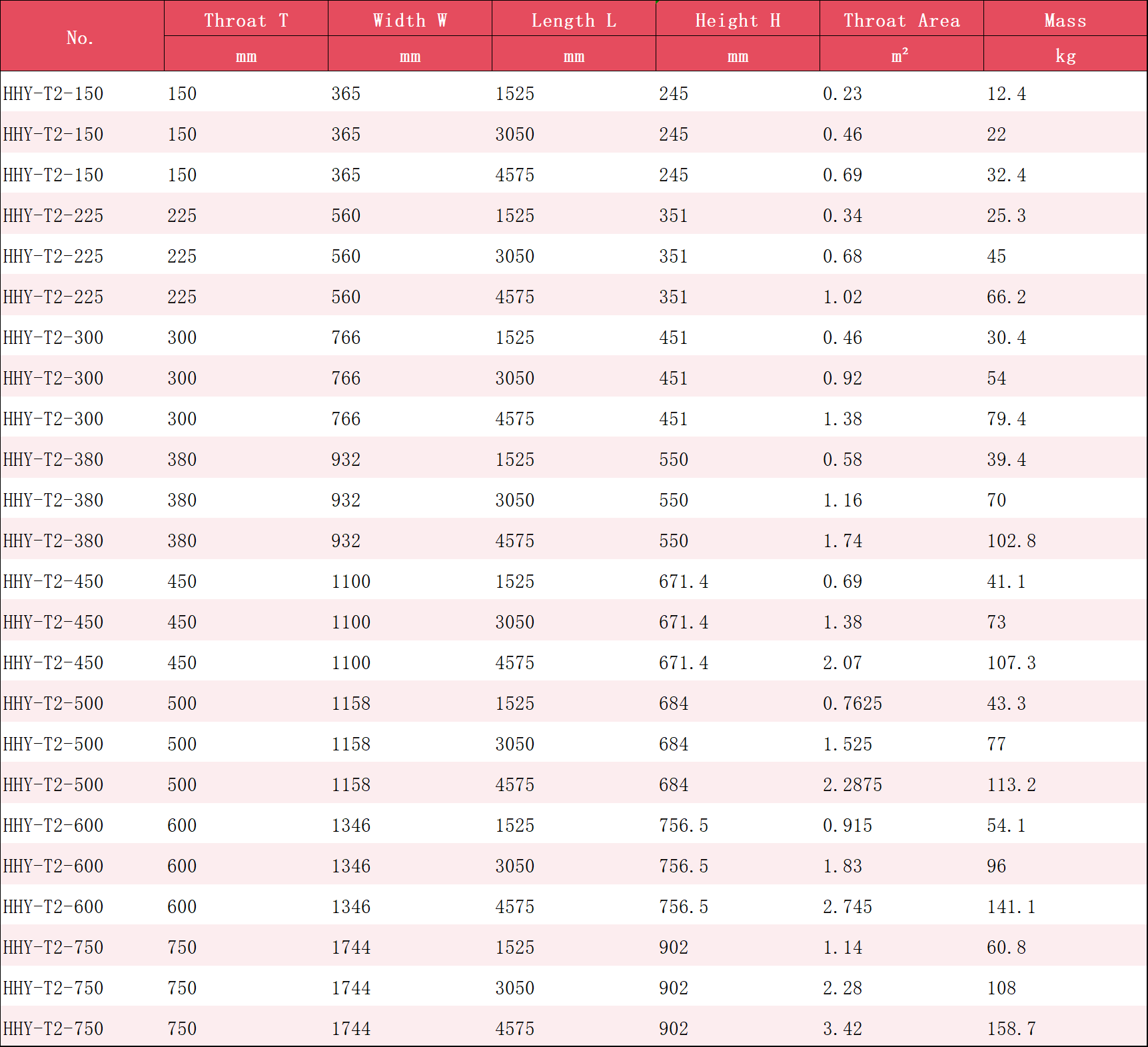

Modular Lengths: Available in 1525 mm, 3050 mm, and 4575 mm modules for flexible roof integration.

4. Cost & Sustainability

Passive Operation: Requires no external power, reducing operational costs.

Energy Saving: By removing hot air and fumes naturally, reduces dependency on HVAC and lowers long-term energy consumption.

Durability: Designed for long service life under industrial conditions, with minimal maintenance required.

5. Specifications & Range

Throat Sizes: 150 mm – 750 mm

Throat Area per Module: 0.230 – 3.420 m²

Mass Range: 12.4 – 158.7 kg per module

Lengths: Standard modules of 1525 mm, 3050 mm, and 4575 mm

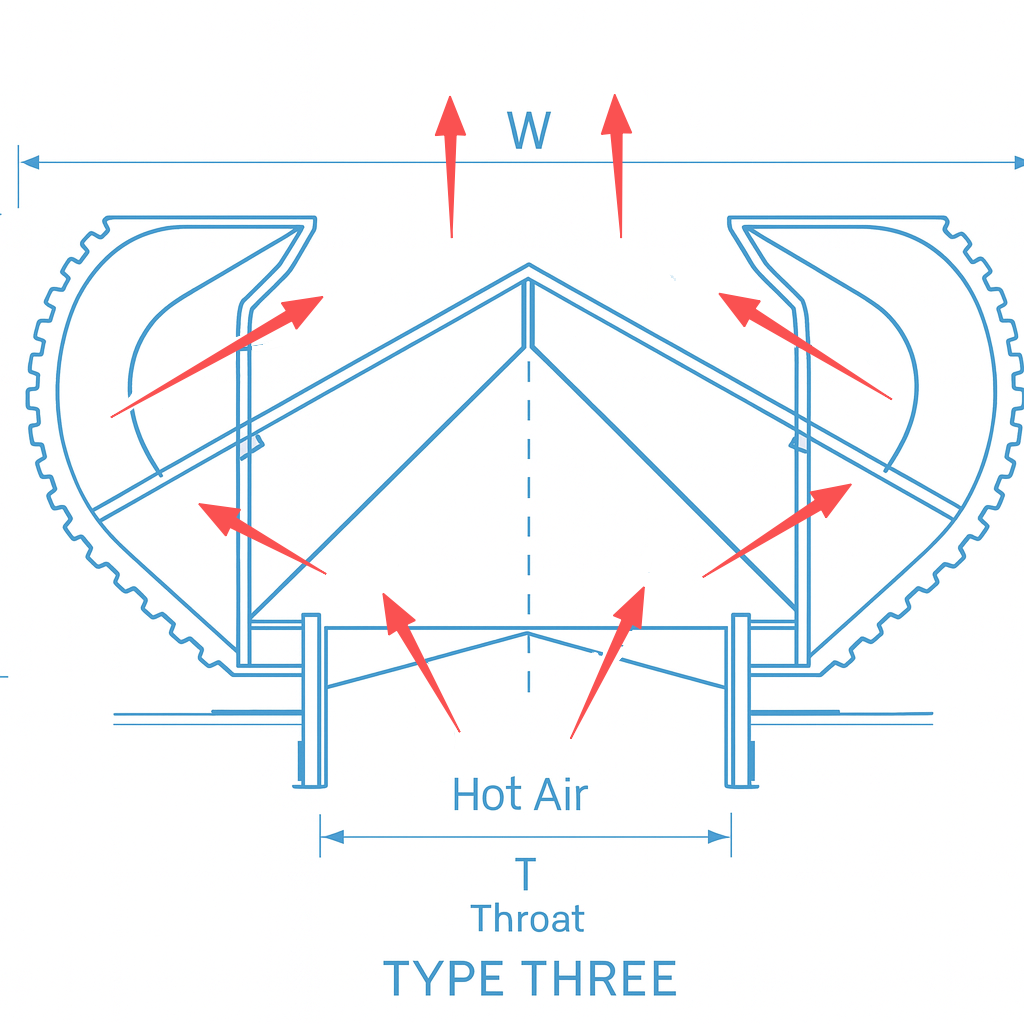

HHY Ridge Ventilator TYPE-3

1. Product Positioning & Applications

Positioning: The HHY-T3 Series represents a large-throat, high-capacity industrial natural ventilator, engineered for facilities with extreme heat loads and large-scale structures. With throat sizes ranging from 610 mm up to 4800 mm, it delivers powerful natural exhaust without the need for mechanical energy.

Typical Applications:

Steel and metal smelting plants

Power generation facilities (thermal, nuclear, combined heat & power)

Shipyards and aircraft assembly hangars

Large-scale logistics warehouses and port terminals

Petrochemical processing plants

Mining, refining, and heavy industrial complexes

2. Technical Performance & Certification

CSIRO Certified Testing: Fully tested for airflow capacity, fire resistance, rain penetration, and wind loading according to AS2428 standards.

Cd Coefficient: 0.65 – 0.75, providing consistently high exhaust efficiency.

Large-Throat Design: Throat widths up to 4800 mm, achieving effective throat areas up to 4.80 m² per meter of ventilator length.

Structural Strength: Designed to withstand typhoons, heavy storms, and extreme wind pressures while maintaining stable operation.

Pressure Relief: Large ventilation cross-sections significantly reduce positive and negative roof pressure, minimizing structural steel demand.

3. Structural & Design Features

High-Profile Appearance: Tailored for wide-span industrial buildings requiring maximum heat and fume extraction.

Integrated Fall-Arrest System: Built-in safety system ensures secure access for inspection and maintenance, meeting international safety standards.

Modular Construction: Available in standard modules from 1525 mm up to 10,985 mm for flexible roof integration.

Deflectors & Drainage System: Advanced guidevanes and drainage channels prevent backflow, water ingress, and accumulation under severe weather.

Maintenance-Friendly: Large accessible structure with inspection paths, designed for long-term reliability.

4. Cost & Sustainability

Zero Energy Operation: Utilizes natural wind and thermal buoyancy, requiring no external power.

Energy Efficiency: Reduces reliance on HVAC and mechanical ventilation, cutting long-term energy consumption.

Durability: Manufactured from high-strength, corrosion-resistant steel, ensuring long service life even in high-temperature or corrosive environments.

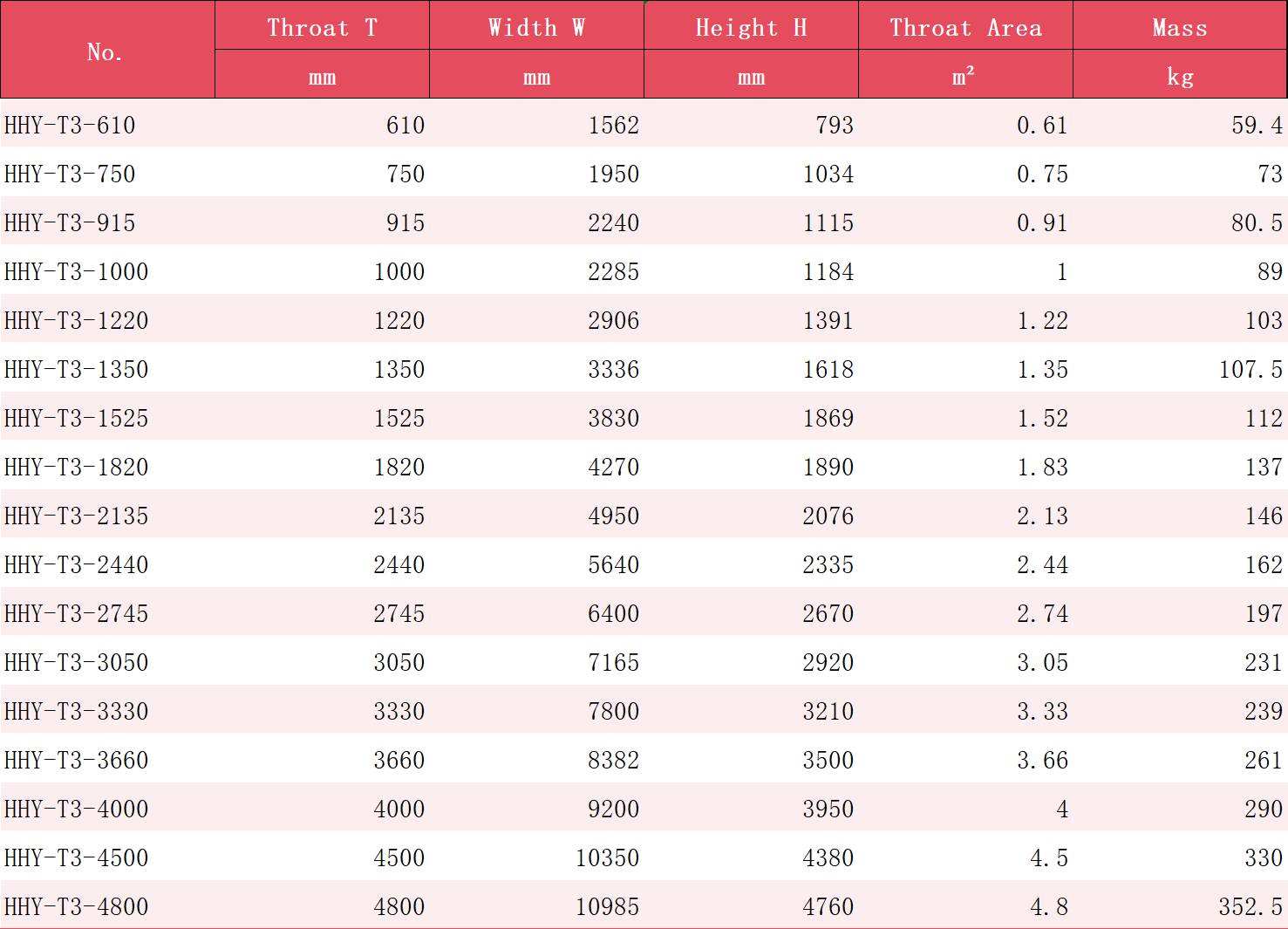

5. Specifications & Range

Throat Sizes: 610 – 4800 mm

Throat Area per meter: 0.61 – 4.80 m²/m

Mass Range: 59.4 – 352.5 kg/m

Height Range: 792 – 4760 mm

Width Range: 1562 – 10,985 mm

Model Codes: HHY-T3-610 up to HHY-T3-4800

Conclusion

Ridge ventilation is not just an accessory but a critical structural component that ensures the long-term functionality, safety, and efficiency of industrial steel buildings. By strategically leveraging the natural stack effect, ridge ventilators provide continuous airflow, effectively removing excess heat, humidity, fumes, and contaminants, while simultaneously improving indoor comfort and protecting building structures.

Through its three product lines—HHY Type-1, Type-2, and Type-3—HHY offers comprehensive solutions tailored to projects of varying scale and complexity:

Type-1 for low to medium heat load environments, with a focus on architectural integration and lightweight design.

Type-2 for medium to high heat loads, balancing airflow performance, modular flexibility, and industrial durability.

Type-3 for extreme industrial conditions, delivering maximum airflow capacity, structural resilience, and safety assurance for the largest facilities.

By adopting HHY ridge ventilation systems, industrial and commercial projects can achieve a harmonious balance of energy efficiency, operational reliability, and long-term cost savings, making them a smart investment for modern building design and sustainable development.