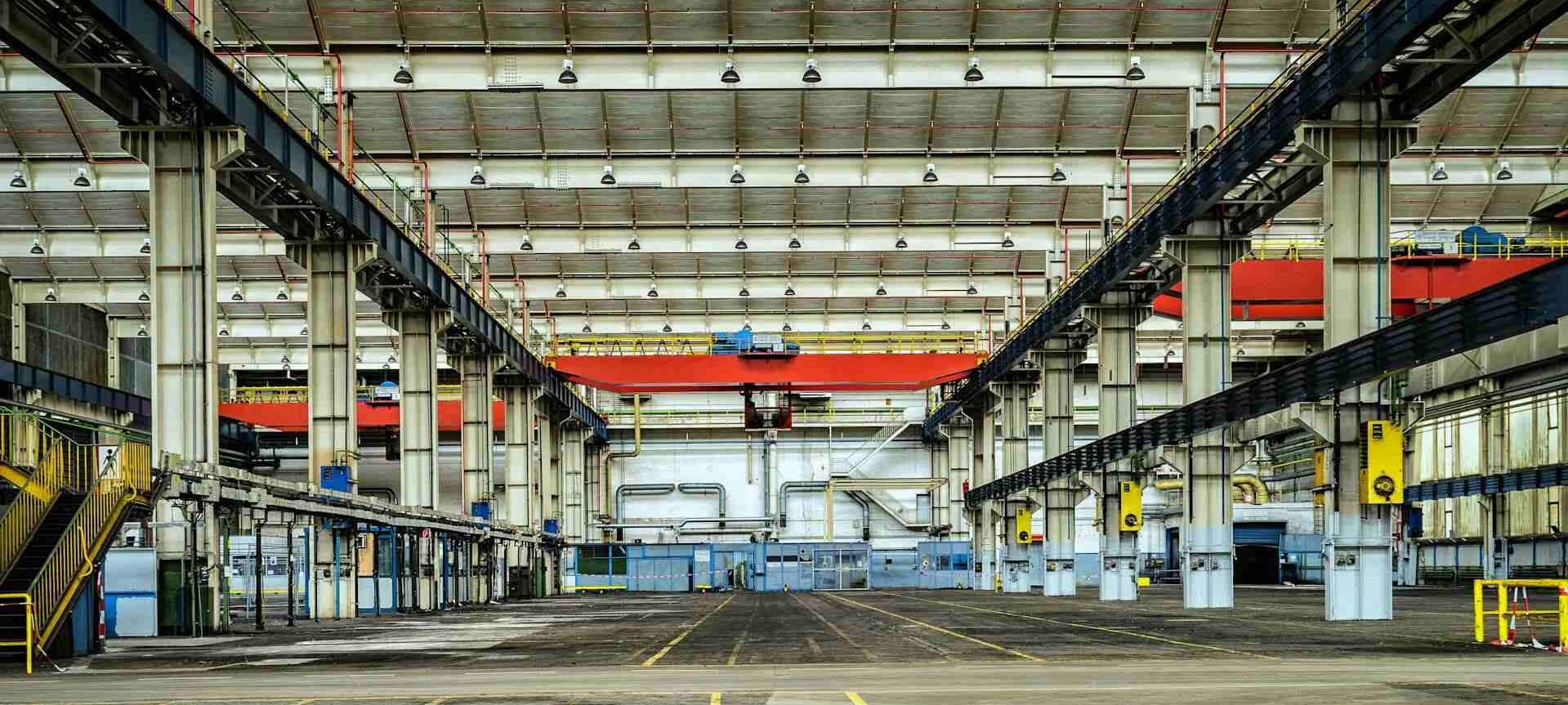

Pre engineered metal buildings are structural systems built from precision-fabricated components manufactured off-site and assembled quickly on location. At HHY Steel Structure, we specialize in high-performance steel buildings that are designed for speed, efficiency, and strength.Originally used for military and agricultural needs in the 20th century, pre engineered buildings are now widely adopted across industries — including steel warehouses, retail outlets, manufacturing plants, data centers, and industrial workshops.

Advantages of Pre Engineered Metal Buildings

Cost-Efficient

HHY’s pre engineered steel buildings are more affordable than conventional structures thanks to factory-controlled fabrication, reduced on-site labor, and minimized material waste.

Key savings include:

-

- Lower Labor Costs: Our integrated process ensures all parts are designed, cut, drilled, and painted before delivery.

- Energy Efficiency: High-performance insulation reduces heating and cooling bills year-round.

- Lower Insurance: Steel structures resist fire, wind, pests, and water — reducing long-term insurance costs.

- Minimal Maintenance: No rot, warping, or termites — just strength that lasts.

Time Savings

Time is money. With HHY, once materials arrive on-site, your building can be erected rapidly, often weeks or months faster than traditional methods.

We streamline the process through:

-

- Single-supplier sourcing for all structural components

- Factory pre-drilling, welding, and finishing

- Local code compliance built into the design

- Fast global logistics and container packaging

- Detailed assembly guides and anchor bolt plans

Reliability and Durability

Steel is one of the world’s strongest and most resilient materials. HHY structures are engineered to endure extreme weather, including heavy snow, strong winds, and seismic activity.

Our buildings comply with global standards like ASTM, EN, and SNI, making them export-ready and reliable.

Customizability

HHY buildings are engineered for flexibility. We offer full customization for commercial, industrial, agricultural, and storage uses.

Options include:

-

- Variable dimensions, heights, spans, and slopes

- Clear span, single-slope, or multi-span frames

- Doors, windows, and skylight customization

- Interior partitions and mezzanine levels

- Multiple cladding styles, colors, and finishes

- Gable, hip, and gambrel roof options

Sustainability

Steel is fully recyclable and long-lasting. HHY’s efficient designs reduce material waste and promote energy-saving practices with solar-ready roofing and thermal insulation packages.

Commercial Applications of Pre Engineered Metal Buildings

HHY buildings are used globally for a wide range of applications:

-

- Warehouses and logistics centers

- Retail stores and showrooms

- Factories and processing plants

- Agricultural structures — barns, storage, greenhouses

- Data centers and tech housing

- Mining facilities, including Bitcoin mining buildings

All buildings are designed to meet local zoning, environmental, and seismic standards.

We work with clients to deliver ready-to-assemble kits anywhere in the world.

*Available Sizes for Pre Engineered Metal Buildings

We offer small, medium, and large-scale solutions:

Small Buildings (<5,000 sq ft)

Storage sheds: 10×12 ft, 12×20 ft

Garages & workshops: 16×24 ft, 20×30 ft

Medium Buildings (5,000–10,000 sq ft)

Retail: 30×60 ft

Garages: 40×80 ft

Barns: 40×100 ft

Large Buildings (10,000+ sq ft)

Distribution centers: 60×120 ft

Factories: 80×150 ft

Steel warehouses: 100×200 ft

Custom sizing and frame layouts available for every industry.

HHY Steel Structure Building Components

Orientation

Proper building orientation improves energy efficiency. HHY helps clients align their steel structures for solar gain in winter and shading in summer, reducing long-term HVAC costs.

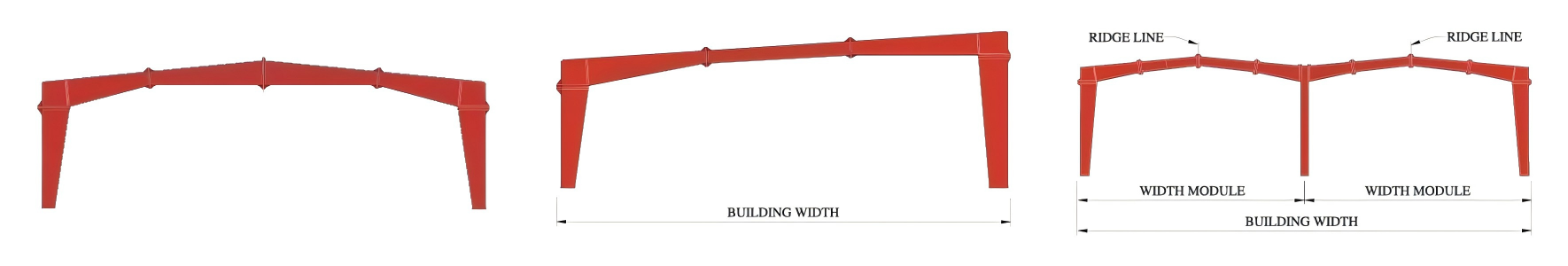

Frame Types

-

- Clear Span – No interior columns, perfect for open floor layouts

- Single Slope – Sloped roof for rain/snow runoff, ideal for lean-to designs

- Multi-Span – Internal columns for extra support in large projects

Framed Openings

All door, bay, and window openings are fully customizable. We offer bi-fold doors, roll-up doors, sliding panels, and glass storefronts.

Panels

Choose from various steel panel styles, profiles, textures, and coatings — all engineered for structural performance and architectural appeal.

Insulation

Options include fiberglass batts, rigid panels, and sandwich-type wall panels. Common systems:

-

- Mesa Wall Panel

- Trapezoidal Roof Panel

- Smooth Wall Panel

- Rock wool or PU core insulated panel

The Cost of a Pre Engineered Metal Building: 5 Considerations

1. Building Design

Larger buildings benefit from economies of scale. A 10,000 sq ft warehouse has a lower cost per square foot than a small storage shed. Share your usage plans and occupancy needs early to optimize cost.

2. Steel Price

Steel is a commodity. HHY monitors market trends and purchases in bulk during favorable conditions to stabilize your budget.

Price fluctuations may come from:

-

- Iron ore availability

- Seasonal demand

- Global shipping disruptions

- Currency fluctuations

3. Fuel and Logistics Costs

Shipping costs vary by destination and container load. HHY uses optimized logistics planning and port partnerships to minimize delivery time and fuel cost.

4. Buying Power

Because HHY owns its factories and buys steel in large volumes, we pass down savings to you. We also offer phased purchasing plans for larger projects.

5. Custom Features

Complexity affects cost. A simple 4-wall structure costs less than a two-story office with glass curtain walls. Let us help you value-engineer your building without compromising performance.

What to Expect from HHY Steel Structure

As a leading pre engineered steel building manufacturer, HHY provides:

-

- Digital 3D modeling and foundation reference drawings

- Numbered and pre-cut components

- Anchor bolt layouts

- Containerized shipping with tracking

- On-site assembly guidance

- Quality control documentation and compliance reports

Selecting the Right Steel for Your Building

Grades & Standards

We use internationally certified steel including:

-

- ASTM A36 / A992 / A500(ASTM International)

- EN 10025 / S355JR(European Committee for Standardization)

- GB / SNI Compliant(中国国家市场监管总局)

PS. The above links are official websites of different standards.

Thickness & Weight

We optimize steel thickness and weight for structural safety and cost efficiency, based on your building’s wind, snow, and load conditions.

Coatings & Finishes

We offer:

-

- Hot-dip galvanization

- Epoxy primer + PU finish

- Powder coating (on request)

- Anti-rust zinc-aluminum coatings

Welding & Fabrication Quality

All fabrication is done by certified welders using AWS-standard welding techniques, followed by visual and ultrasonic inspections.

Certification & Testing

We offer:

-

- ISO 9001 Quality Management System

- Mill Test Certificates

- Material Tensile/Impact Tests

- Chemical composition reports

Supplier Credibility

With over 50,000 sqm of workshop area, in-house engineering, and projects in 20+ countries, HHY has the scale and experience to guarantee results.

Cost vs Value

A cheaper building today could cost more tomorrow. HHY structures are built for long-term ROI, minimal maintenance, and scalable expansion.

Sustainability & Lead Times

We prioritize:

-

- Use of recycled or low-carbon steel

- Compliance with green building codes

- Short lead times with flexible delivery plans

Take the Next Step with HHY

We’re passionate about turning complex visions into steel reality. Let’s bring your project to life — quickly, efficiently, and globally.

📩 Get a Quote: info@hhysteelstructure.com

🌐 Visit Us: www.hhysteelstructure.com

HHY Steel Structure — Global Expertise. Factory Direct. Built to Last.