From Material Advantages to Regional Adaptation: A Technical Guide

Light steel roof trusses, as a representative of modern construction technology, have gained popularity in climatically complex regions such as the Middle East, Southeast Asia, and Indonesia due to their lightweight, high-strength, and rapid installation features. This article will delve into the core advantages and technical details of light steel roof trusses from the perspectives of material performance, construction processes, and regional adaptability, providing practical insights for construction professionals.

I. Core Advantages of Light Steel Roof Trusses

Lightweight & High Strength with Seismic Resistance

-

Light steel material has a density of 1/4 that of concrete and a tensile strength of 550 MPa, making it suitable for large-span designs (e.g., 30-meter industrial buildings).

-

Seismic performance: Flexible structures can withstand earthquakes up to Magnitude 9, offering significant advantages in seismically active regions like Indonesia.

Material Comparison

| Material | Density (kg/m³) | Tensile Strength (MPa) | Suitable Span (m) |

|---|---|---|---|

| Light Steel | 7850 | 550 | 6-30 |

| Reinforced Concrete | 2500 | 30 | 3-12 |

| Wood | 500-700 | 50-100 | 3-15 |

Weather Resistance & Environmental Sustainability

-

Anti-corrosion & Termite Resistance: Hot-dip galvanizing process (zinc coating ≥180g/m²) resists high-salt air in the Middle East and humid environments in Southeast Asia, with a lifespan exceeding 50 years.

-

Eco-friendliness: Material recycling rate exceeds 90%, construction waste reduced by 80%, complying with Green Building Standard 912.

Construction Efficiency

Prefabricated production increases on-site installation efficiency by 60%, with a 200㎡ roof structure completed in 3-5 days .

II. Light Steel Profiles and Design Standards

Profile Classification & Selection

-

C-shaped Steel Truss: Main beam structure, spans up to 30m, thickness 1.2-2.0mm.

-

Light Steel Keel: For walls and floors, thickness 0.6-2.0mm, suitable for low-rise residential buildings.

Application Scenarios

| Application | Recommended Profile | Thickness (mm) | Galvanization (g/m²) |

|---|---|---|---|

| Coastal Residential | C-shaped Steel | 1.5 | 275 |

| Inland Industrial Buildings | Reinforced H-shaped Steel | 2.0 | 180 |

Design Standards

-

Middle East: Follows the *Cold-Formed Thin-Walled Steel Structure Design Code (GB50018)*, emphasizing zinc coating thickness and wind pressure resistance.

-

Southeast Asia: Complies with the *Technical Specification for Low-Rise Cold-Formed Steel Buildings (JGJ227)*, focusing on seismic joints and drainage slopes.

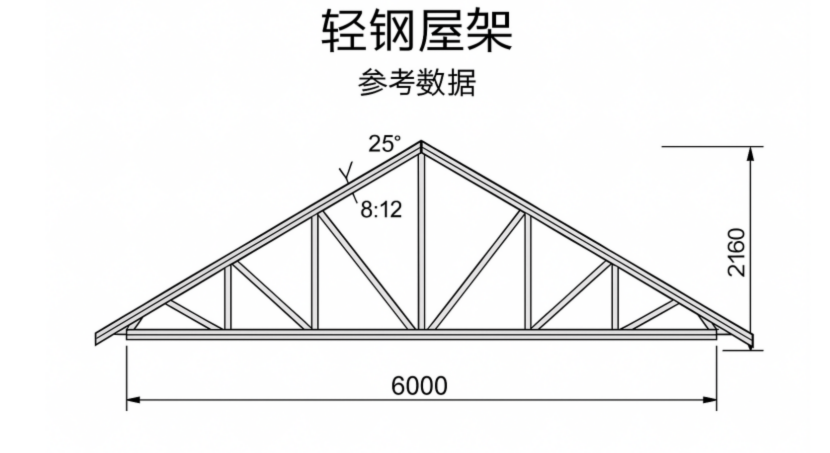

III. Installation Process and Technical Key Points of Light Steel Roof Trusses

Standardized Construction Steps

-

Foundation Preparation:

-

Use strip foundations or isolated foundations.

-

Horizontal tolerance must be <3 mm/m.

-

-

Frame Assembly:

-

Bolted connections (strength ≥ Grade 8.8).

-

Joint spacing ≤300 mm.

-

-

Roof Covering:

-

Adjust batten spacing based on materials:

-

Metal tiles: 400–600 mm

-

Solar panels: 300–400 mm

-

-

Roofing Materials

| Material | Batten Spacing (mm) | Fastening Method |

|---|---|---|

| Metal Tiles | 400–600 | Self-drilling screws + waterproof washers |

| Asphalt Membrane | 200–300 | Welding or adhesive bonding |

Regional Adaptation Techniques

-

Middle East:

Use high-reflectivity roof panels (e.g., aluminum-zinc alloy panels) to reduce heat absorption by 30% and lower air conditioning energy consumption. -

Indonesia:

Add ventilation layers and wind-resistant tie straps to address humid climates and typhoons.

IV. Future Trends and Technological Innovations

Smart Construction

-

BIM technology-integrated design:

Tolerance control <2 mm, project timeline reduced by 30%.

High-Performance Steel

-

Replace Q235 steel with Q550 high-strength steel, decreasing steel usage by 20%.